Global Expertise in Axle Manufacturing, AxleTech

US-based AxleTech is a leading manufacturer of axles for speciality applications in off-highway and defence segments. The company has established a strong presence in Indian market and is experiencing double-digit growth in the country. In an interview, Amit Verma, Director, Business Development, India/South East/Asia Pacific, AxleTech, talks about the company’s Indian operations, its R&D and manufacturing activities in the country and growth prospects. Excerpts

Director, Business Development, India/South East/Asia Pacific, AxleTech.

Q. Tell us about AxleTech’s establishment, operations and journey in India?

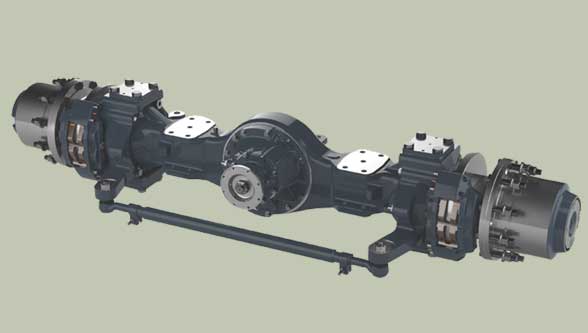

AxleTech is a more than 100-year old company based out of Troy, Michigan. It started with building axles for trucks/vehicles at its plant in Oshkosh, Wisconsin, which is one of the oldest plants to manufacture commercial axles. AxleTech also has its own gear manufacturing unit in the US. Its European headquarters is in Saint Etienne near Lyon, France and also has operations in China in partnership with Fuwa, pioneers in trailer axles and truck axles. Our India subsidiary headquartered in Delhi has manufacturing base in Pune and engineering design centre in Bengaluru. We registered the company in 2012 and the plant was operational in 2015 where it assembles axles for reach stackers, forklifts, and specialty pick-and-carry cranes, besides building axles for logistical & tactical military vehicles.

Q. Which key industries do you cater to? Please shed light on the challenges in reaching out to your target segment?

Globally, AxleTech is into off-highway segment. Our products are used in construction, mining, material handling, ground support, and in defence. Always the challenge for any engineering company to reaching out to the market is the price. There is always lead-time as a challenge as AxleTech is not into run of the mill axle standard catalogue-built axle manufacturer. We are a company, which always produces specialty axles required for very specific application, and turnaround can be very high if not planned. However, the requirement comes very urgent sometimes. In developing countries like India and South-east Asia, you cannot extent the time requirement and ask customer to project demand for next 9-12 months unlike in Europe, US or Japan where accuracy of forecast even for specialty equipment can go as high as 24 months.

Q. Update us on your R&D initiatives in India? Do you have product development and manufacturing facilities in India to cater to your global requirements?

When we started our activities in India almost a decade back, the research and development (R&D) support was mainly from our European engineering head office in Saint Ettiene, France and from Troy, Michigan in the US. Slowly we built up our team here in India. Today, the technology centre in Bengaluru helps us in developing more axles required for Indian market.

Our engineering center in Bengaluru also works for designing, developing and implementing solutions required for off-shore applications.

We also have a manufacturing plant in Pune, wherein we can produce 1,000-2,000 axles a year in one shift. All our axles are for special applications and they are produced and shipped on order. Most of the axles we produce are made-to-order and very specific to that customer and applications. All axles are different from each other.

Q. How do you ensure timely delivery? Tell us about your after-market service.

In India, our products have a high localisation content of more than 80% for most of the programmes. Therefore, we are able to reduce the lead-time to an average of three months, which can further be narrowed down to two months from taking the order to shipment of the product.

We have set up a complete After Market Segment (AFM) to cater to the requirements of both OE spares as well as replacement spares, as the lifecycle of traditional AxleTech products are higher than average axle. We focus on markets such as commercial trucks, brakes, and other perishable including parts beyond axle portfolio. Brand AxleTech is not yet a household name but carries a

value to niche customers who deal with it. Competition is higher in AFM but so is the market size and potential.

Q. What is your differentiator? How do you stay ahead from competition?

Ours are technology products and we do not deal with commodity products. Therefore, we do not have a price list and catalogue. We deal case-to-case, customer-by-customer, program-by program and application-by- application. AxleTech has invested in India by setting up a manufacturing plant in Pune, engineering and design office in Bengaluru, while sales and head office in Delhi for our key customers in the region. Our products are our differentiators. The plant was set up and operational since 2015, but sales service and application support were provided long before. As a result, AxleTech has strong footage on the ground. We are growing faster than the market as we cater to several different market segments and applications. We are not just dependent on one segment, for example, military which is very cyclic in nature and has ups and down. We have made strong headways towards segments like material handling, construction, mining, ground support equipment etc.

Q. Tell us about your recently introduced AFE series of electric powertrain systems.

AxleTech is known for providing world-class solution in driveline with special focus on off-highway market and application such as material handling, construction, mining, ground support equipment and military. AFE series of electric powertrain is about the complete integrated package of axles with motor/inverter and VCU. AxleTech not only provides the E axles but also helps in integrating the axle with the propulsion. Key advantages of AFE are superior power-to-weight ratio, can come with a variety of reduction ratio and have planetary wheel ends, and multiple brake options are also available depending on the application requirement. Like AxleTech solution for traditional drivelines, which caters to specialty trucks and machines, AFE also has similar features, benefits and advantages.

Q. Update us on the average life of an AxleTech product?

It depends on the type of applications and environment it is being operated. For India, we have seen there are machines of our old customers which are running for 30 years without any problem. Normally, axles of AxleTech will not encounter any problem for the first 10 years if they are maintained according to the manual.

Q. What are your growth prospects in India?

We are growing much faster than the market for the reason that our base was negligible and we have a variety of applications. Even in commercials, we have as many as 35 different applications. In defence, we are building axles according to the requirement of the Indian Defence. That is helping us a lot. Our growth combining both commercial and defence is in double-digits.