Robotic welding is rapidly gaining ground in the welding industry. It imposes increasing demands on welding devices, particularly with respect to usability but also for welding quality and productivity. Kemppi is responding to this challenge by introducing the A7 MIG Welder solution, designed specifically for robotic welding.

The solution combines special MIG/MAG welding devices, application software, and welding programs in a system that is compatible with all welding robots and very fast and easy to implement. The welding programs have been optimized for automated welding, and the Wise application software maximizes your productivity, increasing the number of welding applications that are now available for automation. The system comes with the Touch Sense Ignition function, which takes the features related to the arc-ignition stage to a completely new level. In addition, the new Web-based interface enables easy management of welding.

Device description

- A7 MIG Power Source 450

- A7 MIG Power Source 350

- A7 MIG Wire Feeder 25 Euro

- A7 MIG Wire Feeder 25 PowerPin

- A7 Cooler, water cooling unit (including a flow sensor)

- A7 MIG Gun 500-g (gas-cooled)

- A7 MIG Gun 500-w (water-cooled)

- Gun cleaning station

- Brackets for the robot, wire liners, and other accessories

Welding programs optimized for automation

In comparison to manual welding, the travel speed is generally faster in automated welding. High travel speed makes it more difficult to focus the arc, and it increases the risk of undercutting. That is why the best result is achieved by using a shorter arc than in manual welding. In the welding programs designed for the A7 MIG Welder, the parameters affecting arc length, for instance, are optimized for travel speeds of 500 mm/minute and higher.

The A7 MIG Welder welding programs cover all of the most common combinations of filler materials and shielding gases used for welding steel, stainless steel, and aluminum, and the number of options is continuously growing. In addition, customized welding programs are available for your specific applications by special order.

Stability and high speed with Wise application software

Maximum productivity is usually the main objective in robotic welding, and Kemppi offers special Wise processes and functions to address this need. Thanks to the A7 MIG Welder solution, all the Wise applications familiar from Kemppi’s FastMig manual welding devices are now available in robotic welding too. WiseFusion constantly keeps the arc optimally narrow and short during spray-arc and pulse welding, which results in deep penetration. In addition, the stable arc achieved by via WiseFusion functionality enables extremely high travel speeds, up to 2,000 mm/min. WisePenetration keeps the welding current stable no matter the stick-out length. The penetration remains unchanged even if the stick-out length is increased. This feature can be utilized for robotic welding in such cases as when the stick-out length needs to be increased to handle hard-to-reach grooves and welding in tight spaces.

The WiseRoot+ welding process enables introducing various special applications in robotic MIG/MAG welding. For instance, WiseRoot+ enables using robotic MIG/MAG welding in many situations that would normally require a TIG process, such as work with demanding root passes. Thanks to this process, these can now be welded from one side without backing. In comparison to TIG welding, productivity is multiplied. In addition, WiseRoot+ enables, for instance, welding a square groove with a single bead without backing on plates up to 4 mm thick. The heat transmitted to the weld pool remains low, so the process can be used for welding in any position. When traditional MIG/MAG welding is used for vertical joints, the direction is often vertical-up, to avoid the risk of defects. WiseRoot+ enables using vertical-down for vertical welds without the risk of such defects: the arc will always remain on top of a controlled weld pool. This technology offers considerable time savings.

The WiseThin+ welding process brings higher quality and productivity to welding of thin sheets. Heat input to the process is lower than in traditional short-arc MIG/MAG welding. This significantly decreases the number of deformations. In addition, the amount of spatter is much smaller, and, thanks to the lower heat input, spatter will not stick to the work piece as easily.

Touch Sense Ignition, for a guaranteed soft and clean start

In many robotic welding solutions for industrial thin-sheet applications, spatter is not allowed at all. For instance, in catalyzer production, spatter automatically leads to rejection of the product. In addition, high welding speed requires rapid stabilization of the arc after the initial stage.

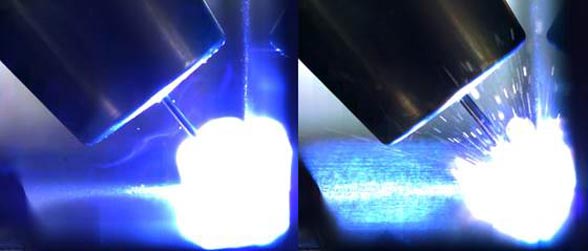

Welding processes and functions that control spatter have been on the market for years already, but even if no spatter is generated during the actual welding, it can, still appear in the initial stage. With the launch of the A7 MIG Welder solution, Kemppi unveils the new Touch Sense Ignition, which smoothens the initial stage of welding and decreases the amount of spatter generated at this point (see Figure 1). This reduces the need for post-welding finishing and results in less wastage.

Further benefits include a lower number of wire feed errors and less interruptions to work, because the amount of spatter sticking to the contact tip is decreased. The smoother initial stage achieved with the Touch Sense Ignition function ensures rapid stabilization of the arc, and it produces high-quality welds right from the start. The function can be enabled and disabled with any welding program.

Centralized control of the system via the Web user interface

To ensure efficient robotic welding with a high-quality result, an easy way of monitoring and controlling welding and the device settings is needed. To meet this need, Kemppi has designed a new browser-based interface for the A7 MIG Welder solution that can be used with all common Web browsers. The most important welding parameters, such as the current, voltage, welding power, gas flow, wire feed speed, and system status, can be monitored via the interface in real time. It enables detecting problems, such as use of incorrect welding parameters, errors in system operation, or shielding gas supply problems, from your computer screen and addressing them without delay. Gas test, compressed air test and wire inch functions can also be performed via the Web user interface. Management of memory channels or welding programs, along with related settings, is very fast and easy. In addition, the Web user interface has a logbook view showing weld information, errors, and changes made to system settings.

All 199 memory channels and the welding programs and settings stored in them can be managed via the same remote control point (see Figure 2). This saves a considerable amount of time and facilitates getting an overview of larger entities than management from individual power sources or robot control systems allows. The person monitoring the welding work can control entire welding projects from one computer.

Summary

Kemppi’s A7 MIG Welder is a versatile solution for robotic MIG/MAG welding. In the design of the devices, particular attention has been paid to usability and features that increase the quality and productivity of welding. Welding programs optimized for automation, the Wise application software, and the excellent usability offered by the Web user interface of the A7 MIG Welder take robotic welding to a completely new level, making features of the future available today.

Author: Antti Kahri, Welding Engineer, Kemppi Oy

For more information

Web: www.kemppi.com