Productivity and Energy efficiency is the most important now to remain competitive in global market. Productivity greatly depends upon the equipment, processes and employees. Productivity can be increased by reducing the downtime of the processing machines, increasing the efficiency of manpower or by having automation in the processes.

Most important challenge observed with any kind of processing unit in India is the downtime of the equipment due to water related issues like corrosion or scaling. Cost associated with downtime of the equipment might be huge compared to investment for eliminating water related issues.

Most often, processors install RO water plant or water treatment to get rid of corrosion and scaling. But even after installing or safeguarding water treatment, processors are facing similar issues due to evaporative cooling towers.

Open loop evaporative cooling towers are the major source of fouling not only in to the piping but also expensive parts of the main machines which causes the need of laborious maintenance as well as replacement of expensive parts.

Another important & big issue associated with open loop evaporative cooling tower is huge amount of water evaporation. On an average, water evaporation in the open loop cooling tower is close to 1 % of water flow rate considering the climate in major parts of India.

To avoid these issues, processors are selecting water chiller even though process does not demand water temperature of less than 30-32 0C. In my opinion, selecting Water Chiller is not wise decision since it consumes lot of energy which results in higher operating expense and cost of product being manufactured. Then what is the alternative?

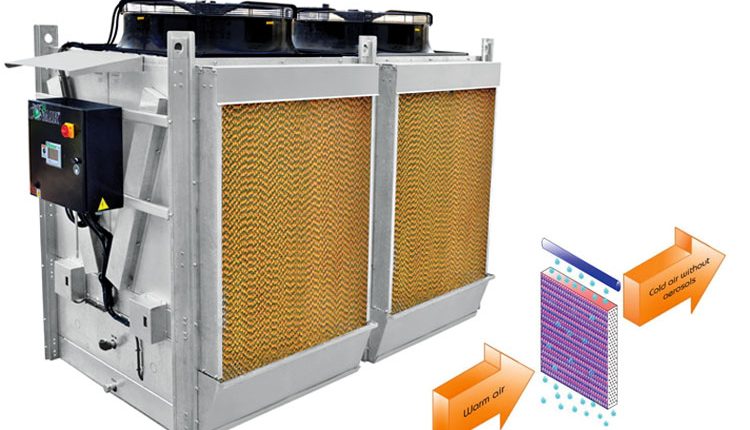

Nu-Vu Conair Pvt. Ltd. has alternate solution to address all above issues by offering ADIABATIC COOLING TOWER – COST-EFFECTIVE & ENVIRONMENT FRIENDLY ALTERNATIVE TO COOLING TOWER.

Adiabatic coolers are a cost-effective alternative to cooling towers due to significant operational savings as well as help in conserving Water. Significantly require lower maintenance compare to traditional cooling tower.

This system works on Dry mode and Adiabatic mode.

Dry Mode – This unit consist of high performance finned and tube heat exchangers & high flow Axial Fans to bring down the process water temperature as close to normal cooling tower water temperature without activating the adiabatic mode up to certain ambient temperature. During dry mode, rate of water evaporation is Zero.

Adiabatic Mode – The units use cold water only when ambient temperature is too high to precool Air whereas normal cooling tower continuously uses the water to produce cooling effect. Precooled Air then cools the process water.

The adiabatic mode activity is tightly monitored using a pulsing mechanism to ensure minimum adiabatic cooling is provided for any given load and ambient condition. This control reduces water consumption and running costs for a long, fault free lifespan.

Advantages

- Cycling of Fans / Optional Speed Control EC Fans – Saves lot of energy during lower ambient or when plant is running at partial load. Adiabatic mode operates only when the ambient air temperature is too high to use cooled air – save lot of money in running costs

- Only uses water by adiabatic mode when high ambient demand higher levels of cooling – conserving water

- No further chemical treatment required – saving resources and budget on water treatment

- Replaces Air Cooled Chiller where Ambient temperature goes above 40 Degree Celsius and help in energy saving with Water Cooled Chiller + Adiabatic Package

- Replaces usage of Chiller where water temperature requirement is 32 oC which reduces the energy consumption cost drastically compared to Chiller

About Nu-Vu Conair Pvt. Ltd.

Nu-Vu Conair Pvt. Ltd., is a joint venture company between Nu-Vu Engineers, Ahmedabad, India and The Conair Group, a leader in auxiliary equipment for plastic processors; headquartered in Cranberry Township, Pennsylvania, U.S.A. Conair has manufacturing facilities in the USA in addition to India and manufactures 450 different products. The company also has two world-class R & D (Research & Development) labs within their facility.

We, Nu-Vu Conair Pvt. Ltd. are a leading manufacturer of plastic auxiliary equipment in India based on world-class technology developed by Conair Group (USA). The products include heat transfer equipment such as chillers and mould temperature controllers, central vacuum conveying systems, drying systems, gravimetric blending systems, crystallizers, belt conveyors, granulators and many more for polymer processors.

After establishing itself as one of the leading supplier of process cooling in polymer industry, Nu-Vu Conair Pvt. Ltd. in 2019 diversified in-to offering process heating and cooling solutions to various other industries such as Diamond Industry, Food & Dairy Industry, Laser Cutting & Machine Tool, Chemical Industry, Aluminium & Zinc Die Casting, Printing Machines, Medical & Pharma, Brewery & Beverages Plant, Welding Machinery, etc. based on the needs of process including negative Glycol Chillers and twin water outlet temperatures. Within two years, we established ourselves as a major supplier in this segment.

Our state-of-the-art manufacturing facility is spread across 1,50,000 Sq. Ft. to manufacture heat transfer products such as Portable Chillers, Central Chillers, Adiabatic Cooling Towers, Heat Exchangers, Pump Tank Units and Temperature Controllers along with other polymer processing product line.