Configure guide shafts with and without machining online, download technical drawings and order directly with new igus online tool

Designing the right shaft for an application is not easy without CAD software and in-depth technical knowledge. igus has now developed a new, free-of-charge and freely accessible online tool with the drylin shaft configurator. In just three steps, the user is given the opportunity to select the right shaft in the required length from seven materials, machine the main body and the machined ends with standard elements such as chamfers and grooves and order the configuration. In addition, the user receives the STEP files of their configuration as well as a dimension drawing for downloading, free of charge.

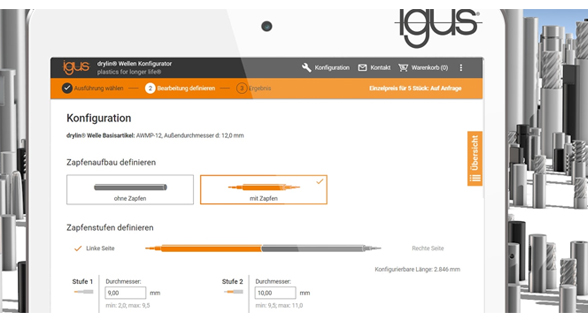

Designing shafts without a CAD programme? igus is now making this possible with its new free online tool: the drylin shaft configurator. This expands the wide range of practical online services. In this way, the user gets to their desired product even faster, without any necessary technical knowledge or CAD software. In the new online configurator, the user can choose between seven different shaft materials with diameters from 6 to 50 millimetres and machine the main body and machined end as they like. Meanwhile, the user gets the price of their configuration and can order it directly. Another advantage: igus provides the STEP file for the shaft and the technical dimension drawing as a PDF download. This allows the user to further design the application directly with the configured shaft.

Fast and simple configuration in just three steps

In the first step of the drylin shaft configurator, the user determines the diameter, the length and the number of required shafts. Then they can choose the right material with the ideal surface treatment. In addition to hard-coated aluminium shafts, hardened or chrome-plated steel shafts, several hardened stainless steel materials and VA shafts are also offered. Stainless steel shafts are very suitable for the food processing industry, while aluminium shafts are a lightweight and cost-effective alternative suitable for mechanical engineering. In the second step, the user can machine the shaft body and optionally the machined ends, and add different machining stages as well as 14 standard elements such as bevels, holes, threads or grooves.

An intelligent system gives the user maximum and minimum values which prevents faulty design. The clear surface of the tool, hints and tips make the configuration of the shaft much easier for the user. In the last step, the customer gets an overview of the configuration including the price as well as bulk pricing and the delivery time. Here they can order the shaft or request a quote, download the dimension drawing and the CAD data of the product. There is also a possibility to save the configuration or to share it with colleagues via a link, which is very practical, especially when designing large projects. After receiving the order, it will be sent digitally to the factory, where the shaft will be manufactured by igus within 3-6 days and then shipped.

iglidur plain bearings as long lasting partners

But what would a shaft be without the appropriate plain bearing or linear plain bearing? The motion plastics specialist igus, has been developing plain bearings made of tribo-polymers for more than 35 years. With more than 50 different materials in different dimensions, igus offers the right plain bearing or the right linear plain bearing with iglidur sliding elements for every application and shaft. The special feature: all iglidur materials are made of lubrication-free and maintenance-free tribo-plastics. These are wear-resistant, lightweight, corrosion-free and withstand even extreme loads.

Share feedback and join the discussion on the Telegram Group

https://t.me/joinchat/