How will materials for additive manufacturing affect transport in years to come?

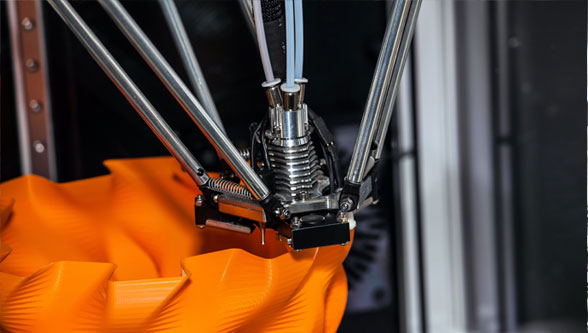

From components for motorcycles to reconstructive moulds for injured motorcyclists, 3D printing and additive manufacturing (AM) technology holds a broad spectrum of possibilities for the transport industry. As these technologies mature, the materials used in the systems must do the same. Here, Ben Smye, head of growth at materials search engine Matmatch, looks at the road ahead for AM materials.

Remarkably, the notion that we would one day be able to construct functional, three-dimensional objects by effectively drawing them was first conceived in 1945, featuring in Murray Leinster’s Things Pass By. The science-fiction short story includes a scene in which a man constructs a spaceship by spraying one layer at a time.

Although it’s a fantastical example, it shows how the longstanding connection between AM and transport predates the advent of AM technology, and even the term itself.

Today, AM promises a wealth of benefits to transport manufacturing. Components manufactured using AM techniques are typically more lightweight than their subtractive manufactured counterparts and boast similar levels of strength and robustness, all while the overall cost of production is lower and manufacturing speed is increased.

AM also opens the opportunity for design engineers to experiment with material structures to improve the integrity of components. The technique makes new designs possible, as more complex components can be produced easily, and it’s easier to produce components with mesh or lattice structures. This means that designers can incorporate these structures into component design, allowing the product to possess the same strength and sturdiness using less material, in turn reducing total weight.

With these factors in mind, it’s no surprise that a 2018 report by the Aerospace Technology Institute estimated that 35 per cent of the total AM market will be driven by the aerospace and automotive industries.

Material selection

For sectors like transport where poor material selection can lead to or exacerbate serious incidents, the choice of materials is critical. And for AM, the source of these materials is also an important consideration.

For example, a 3D printed metal component for aircraft might experience limited density due to porosity, which can lead to cracking and material fatigue. This can occur due to the AM process itself, but it is also symptomatic of a poor-quality metal powder feedstock introducing gas pockets into the process. Sourcing metal 3D printing powders from reputable suppliers, via platforms such as Matmatch’s materials database that partner only with reliable material suppliers, solves this issue.

Comprehensive materials databases such as these also give transport design engineers a greater understanding of the many materials available for AM. Although many people think of polymer filaments as the primary choice, metal — of all types, from stainless steel and aluminium to cobalt and titanium — and ceramic powders are also widely used.

This flexibility of material types means that design engineers can additively manufacture many of the components required for various modes of transport. For cars, a brake caliper could be 3D printed using a titanium powder, which would offer a lightweight and high strength product ideal for this application. Alongside this, the pistons for the caliper could be 3D printed from phenolic resin to provide durable, corrosion-resistant properties.

We’re also increasingly seeing alloy materials appear in AM-suitable feedstock forms, providing further opportunities for 3D printing in transport engineering. Materials such as VDM Metals’ Powder 625 or Deutsche Edelstahlwerke’s Printdur® Ni625, both of which are powdered nickel-chromium-molybdenum alloy for 3D printing, exhibit enhanced corrosion resistance due to their composition, making the alloys a good fit for components on ships and seafaring vehicles.

And as the range of materials expands, we see a similar trend towards sustainable and ‘green’ materials emerging, as can be found in the wider materials sector.

Sustainability and the road ahead

Additive manufacturing as a process is more efficient and less wasteful than conventional, subtractive manufacturing. Not only does the process itself use less raw material as it can be more precise, but the technique is typically used to produce parts to specific demand, effectively eliminating the need for excess production.

This subsequently lowers the energy usage of the process. In fact, a 2014 study by Gebler, Uiterkamp and Visser stated that 3D printing has the potential to reduce the total primary energy supply by 2.54–9.30 exajoules, and lower CO2 emissions by up to 525.5 megatonnes by 2025.

It stands to reason that AM will continue to become more widely used in many industries, and this offers a unique opportunity for transport design engineers. It allows for greater experimentation of materials, at a low-cost, to reshape what we consider to be conventional vehicle design. And given the quick prototyping and production time and minimal overheads, it will give design engineers an unprecedented level of freedom.

To further exemplify this, we can look at GE Aviation. Using additive manufacturing techniques, the company’s Catalyst Advanced turboprop engine consolidated 855 components into a mere 12. These changes to conventional designs further reduce the total production costs. So, why wouldn’t transport design engineers experiment with design concepts using this maturing technology and advancing additive manufacturing materials?

Almost three-quarters of a century after the first connection between 3D fabrication and transport was first made, we are inching ever closer to it becoming a widespread reality. We might not yet be at the stage where we can spray a spaceship into existence, but if design engineers experiment and don’t let this opportunity pass by, this could be a stop on the horizon.