Flexible connection of industrial networks

Project at a glance

Company: Schneider Electric,Solution: High-End Gateway NT 100, Country: Argentina, Key Contact: Rogelio Hernández, Timeline: 12 Months

“Hilscher offered a highly flexible solution in a compact format that came with an easy-to-use programming tool for fast configuration.”

Rogelio Hernández, Automatism Project Leader Schneider Electric Argentina

Sometimes great solutions come in a surprisingly small package. Such as the Gateways of the netTAP series from Hilscher. At a lithium carbonate processing plant in Argentina they proved to be a costeffective solution to integrate proprietary protocols into the automation system. Schneider Electric is a global player that takes a leading position in fields such as electric energy supply, process automation and control systems as well as building management. The company has some 170,000 employees worldwide in more than 100 countries. Schneider Electric Argentina Services is an Argentina based subsidiary of Schneider Electric which is primarily engaged in the realization of industrial process automation projects.One of the customers of Schneider Electric Argentina was a mining company located in the Jujuy province of Argentina. The company recently started operating a plant for the production of primary lithium carbonate. Lithium does not appear as a pure element in nature but is contained in either specifi c rocks or in bine bodies within salt lakes (sales). For the production of lithium carbonate, the mining company exploits a large salt lake located in northern Argentina. The newly erected plant for mining and processing is located at high altitude with corresponding low temperatures, as well as low oxygen and air pressure levels. The plant covers a large area and consists of several sub-plants.

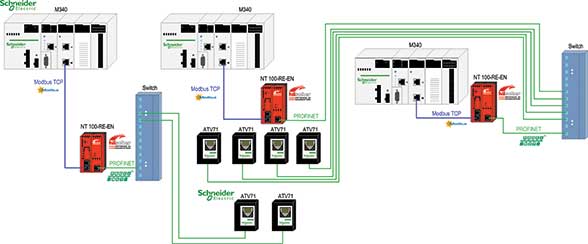

The process plant uses third party controllers to monitor field IOs and other devices that are connected via a PROFINET communication infrastructure. For a large number of sub-processes throughout the plant the mining company decided to obtain variable frequency drives (VFD – ATV71) and the related Motor Control Cells (MCC – M340) from Schneider Electric. These Schneider MCCs are equipped with a communication front end that uses Schneider‘s proprietary protocol to communicate with their IOs.

Dilemma between system worlds

In order to establish seamless process control to drive the automation system of the plant and its sub plants, Schneider Electric‘s customer wanted to integrate a solution to monitor and control the MCC field IOs complementary to the VFD control. This required some type of solution to translate the proprietary IO signals into the standard PROFINET protocol used throughout the plant.In other words, Schneider Electric was confronted with a requirement that initially seemed to be anything but trivial. One option that the project team identified involved exchanging all IOs by other PROFINET compatible devices. But this approach was quickly discarded because it proved to be much too cost-intensive for the customer. Another approach would involve a rather complex integration into the MCC standard communication front end of the company. In other words, although both solutions were generally feasable, they also involved considerable drawbacks. After all, seamless integration of the Schneider Electric motor control cells and variable frequency drives called for creating a communications bridge between two protocol worlds. The automatism team at Schneider decided to start a comprehensive market analysis. They communicated with various vendors to find a cost-effective solution for this particular project and eventually ended up with Hilscher. The German company headquartered in Hattersheim in the southwest of the country has more than 230 employees in 10 countries worldwide. The company focusses on development and production of industrial communication solutions for Fieldbus and Real-Time Ethernet as well as on ASIC technology for modern factory automation. “Hilscher offered a highly flexible solution in a compact format that came with an easy-to-use programming tool for fast configuration,” Rogelio Hernández, Automatism Project Leader at Schneider Electric Argentina justified the solution he recommended Project Manager Edgardo Enz to this mining plant project.

Translating between protocols and systems

The product that fulfilled all the requirements of the Argentinan process plant was the NT100-RE-EN Gateway of the Hilscher netTAP 100 range. This high-end Gateway was especially designed for demanding conversions. It is a highly versatile PROFINET IO Controller to EtherNet/IP adapter. It supports slave and master functionality in any combination. Apart from standard protocols, the Hilscher netTAP 100 Gateway NT100-RE-EN supports the creation of serial protocols with the help of the Lua-based scripting language netSCRIPT. The Schneider Electric project team was able to use a fully featured development environment that came as a standard feature of the package. It allows comfortable and rapid programming of any proprietary serial protocol as well as the IO data pre-processing during the conversion into another field protocol. For mining plant, the Hilscher solution proved to be a very cost effective way to synchronize the Schneider Electric communication protocols with the open PROFINET world. It allowed the company to use the variable frequency drives (VFD) and the related Motor Control Cells (MCC) from Schneider Electric with proprietary IO communication and still establish seamless process control from the PCS all the way down to field device level.

Solution with future options

The mining process plant automation project proved to very time consuming. After producing the MCCs that needed to be tailored to the specifi c application, a comprehensive factory acceptance test (FAT) was required. After that, the equipment needed to be transported from the factory to the remotely located site of the lithium carbonate production plant. After assembly at the plant, the complete automation system had to go through a site acceptance test (SAT).The Hilscher Gateway considerable added to an accelerated system implementation and proved to be a highly fl exible solution that is open for future expansion and added functionality.“We were able to establish a standard way to integrate our M340 platform with PROFINET controllers, so they can act as remote IO for any type of PROFINET controller,” Rogelio Hernández commented on the solution and added: “The Gateways greatly simplify any implementation that involves the use of Schneider MCCs in combination with VFD, soft starters or any direct outputs.” He also sees future applications that can be realized in a fast and efficient way: “By extension, this solution can be used with any process controlled via PROFINET that needs to interact with the Schneider automation platform.” The UL certifi ed Hilscher Gateway PROFINET IO Controller to EtherNet/IP Adapter is an inconspicuous device that measures only 100x52x70 mm and matches the DIN rail of any standard switching cabinet. Yet, it is a highly versatile component that can be programmed easily to match any application calling for process control signals to be translated between system worlds.

You want to get information about our Gateway solution?

netTAP 100 is the protocol converter for sophisticated conversions and, in addition to serial/fi eldbus to two port Real-Time Ethernet conversions, it also supports fi eldbus to fi eldbus conversions and it supports slave and master functionality in any combination. There are no restrictions on the master functionality which requires a master license.

“By extension, this solution can be used with any process controlled via PROFINET that needs to interact with the Schneider automation platform.”

Rogelio Hernández, Automatism Project Leader, Schneider Electric Argentina Motor Control Cells M340 – Schneider Electric

For more information

E-mail: [email protected]

Web: www.hilscher.com