World’s first safe & rugged radar system

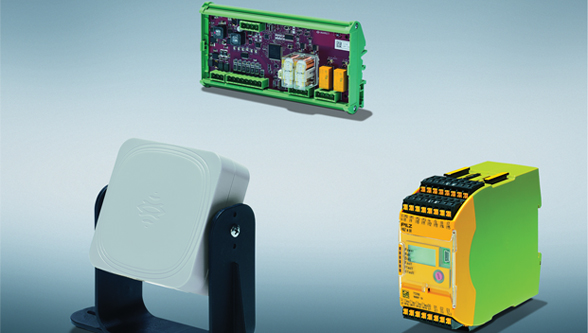

New to the Pilz portfolio is the world’s first safe complete solution for protection zone monitoring, based on radar technology. It comprises the safe radar system “LBK System” from Inxpect S.p.A. and the configurable small controller PNOZmulti 2. This complete solution provides safe, economical monitoring even in the must rugged environments – in extreme production environments such as dust in woodworking for example –or with complex plant structures.

Benefits of the safe radar system solution include high plant or machine productivity, despite the most rugged environment.The safe radar system solution expands the Pilz portfolio in the safe sensor technology range PSEN.

System solution comprising radar sensor and controller

The safe radar system solution comprises up to six radar sensors and one control unit, depending on the application. Add to that the configurable safe small controller PNOZmulti 2, which is responsible for safety in the solution. In the event of a fault and when the protection zone is violated, PNOZmulti ensures that the reaction that is triggered is safe and reliable. The safe radar system solution can be used up to SIL 2, PL d, Category 2.

The safety-related functions covered by the system solution include the “detection function”,i.e. when a machine is switched to a safe state as soon as a danger zone is violated, plus the restart interlock, which prevents the machine starting automatically if there is anyone in the danger zone. The layout for a protection zone is flexible: each sensor has a maximum range of 4m, and can be configured with a narrow or wide coverage area, 50º horizontal and 15º vertical, or 110° horizontal and 30° vertical, respectively.

Flexibility and modularity

The layout of the protection zone and system at the site where the safe radar system solution is used can be designed modularly, by freely combining multiple sensors, each individually configurable. The protection zone of each sensor can be set up as wide or narrow, depending on the characteristics of the area to be monitored. A wide protection zone covers a horizontal opening angle of 110° and a vertical opening angle of 30°. A narrow protection zone has an opening angle of 50° horizontal and 15° vertical. The actual protection zone of the sensor depends on the height at which the sensor is installed, the inclination (horizontal/vertical) of the sensor, and its configuration in terms of alarm range, which can be up to four meters. The system solution can even develop a variety of protection zones via the number and inclination of the sensors, e.g. to form a circular arrangement.

Versatile configuration

The system is modular, with a configuration of one to six sensors. When required, more systems can be used to extend the coverage area. Integrated muting can temporarily exclude sensors, configured in up to three groups. The free Inxpect Safety software configurator enables you to select the sensors and their configuration. An additional warning zone can be configured here as an option. This saves time, plus the machine can be put into service more quickly.

No problems with dust and dirt

The safe radar technology on which the system solution is based is fundamentally insensitive to externa influences such as dust, rain, light, sparks or even shock. So the safe radar system solution can be used anywhere that optoelectronic sensors and technologies cannot guarantee availability. In addition to safe area monitoring with the safe laser scanner PSENscan or the light curtains PSENopt, the world’s first safe radar system solution also provides a productive solution in extremely rugged environments – for outdoor use, in heavy industry or woodworking for example. Typical applications can be found in heavy industry, where dirt, dust,swarf or welding sparks, bright light and shock are prevalent. This includes steel processing, foundries or woodworking. Outdoors, the radar system solution safeguards cranes and floor conveyor systems,bulk cargo ports or storage facilities even in fog, snow and up to moderate rain.

The Pilz Group

The Pilz Group is a global supplier of products, systems and services for automation technology. Based in Ostfildern, near Stuttgart, the family-run company employs around 2,500 people. With 42 subsidiaries and branches around the world, Pilz supplies safe solutions for people, machinery and the environment. The technology leader offers complete automation solutions comprising sensors as well as control and drive technology – including systems for industrial communication, diagnostics and visualisation. Consulting, engineering and training round off its international range of services. In addition to mechanical and plant engineering, solutions from Pilz are used in many sectors such as wind energy, railway technology and robotics.