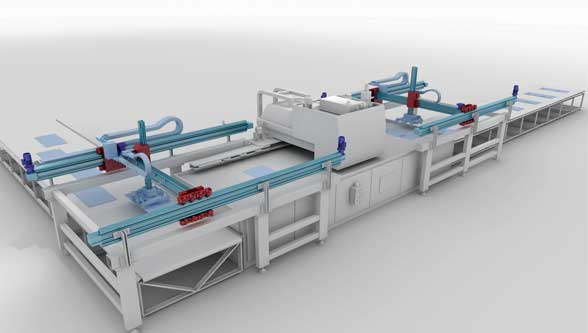

Rollon’s linear rails with plastic compound coated rollers can work for over 80 thousand km with practically no maintenance. This drastically reduces machine down time, provides a crucial advantage for improving productivity in automated processes, and makes our clients more competitive. 80,000 Km without planned maintenance. This is the main strong point of the self-supporting Speedy Rail product by Rollon, which is specialized in linear motion solutions. Integrated into the company’s range after the acquisition of TMT, Speedy Rail is an important tool for optimizing productivity in automation processes, reducing operating costs and eliminating machine down time intervals due to re-lubrication operations. This is an important advantage for efficiently fulfilling the needs of our clients with regard to automated applications in the automotive, packaging, and medical machines sectors, as well as different processing operations for materials such as metal sheet, ceramics, marble, glass, wood and metals.

Which technical features make this type of performance possible? Let’s find out.

A low noise producing system that requires zero lubrication Speedy Rails are structural self-aligning structural rails made of hard, deep anodized extruded aluminum and steel bearings coated with plastic. This material, combined with the lifetime lubrication of rollers with high performance grease, renders maintenance on the rails and rollers almost unnecessary. In fact, they can work up to 80,000 km without requiring any maintenance operations. Even in the dirtiest environments, Speedy Rail guarantees excellent results: the special plastic compound used to make the rollers allows them to work without protection even if in environments with welding spatter and abrasive dust, such as workshops where ceramics and tempered glass are produced. Rails designed to work without lubrication offer many benefits in addition to saving money and increasing productivity, which, nevertheless, are certainly very important. Dispersion of oil and grease into the work environment becomes a thing of the past, along with noise. Thanks to the plasticcoated rollers and the rail structure, Speedy Rail guarantees very silent operation, in compliance with increasingly strict laws and standards that classify noise as a significant risk in the production environment.

Quick assembly and self-alignment…

Resistance and reliability go hand in hand with speed and easy assembly: this single product is made up of self-aligning rails with a structure and sliding system that requires only a few support points instead of finished metalwork structures. Moreover, simple joining kits are all that is necessary to ensure that the rails can withstand an unlimited stroke (these self-centering mechanisms have plates and dovetail joints). For parallel rails, the Speedy Rail rollers and supports are able to compensate for parallelism errors of up to 8 mm. This high flexibility means that installation time is reduced to a minimum, regardless of the production sector, and this advantage saves a considerable amount of money.

…without giving up high performance

Speedy Rail guarantees high performance, with speeds up to 15 m/s and accelerations up to 10 m/s2. The product also offers a great load capacity, higher than 3,000 kg for gantry configurations with 4 sliders and 8 rollers. They can be used as linear rails or actuators, and can be operated with a belt or rack and pinion drive. They are available with V type and cylindrical rollers, in five different sizes: 60, 90, 120, 180 and 250mm. In addition to individual components – rails, rollers and supports – with which clients can build their own systems, a wide range of linear models is available with belt or rack and pinion drives. If necessary, these systems can be customized. The Rollon technical office is happy to help clients during each phase, from defining their system layout to start up, and offers technical assistance for the entire product life cycle.

Information about Rollon

Rollon Group has its headquarters in Italy and offices in Germany, France, the United States, China, India, and Japan. It produces linear and telescopic rails and actuators for many sectors, such as railway, aeronautical, logistics, packaging, machine tools, and medical. Numerous end markets and a vast clientèle are Rollon’s strong points. The company is known for high quality standards in its products, pre-sales support and product customization. All these characteristics have made it a leader outside of Italy as well, where 85% of production is sold. Thanks to the its growth strategy in recent years, the Italian company has positioned itself as a provider of increasingly complete linear motion solutions, while strengthening its position in the industries of automation and robotics.

For more information:

ROLLON INDIA Pvt. Ltd.

1st floor, Regus Gem Business

Centre 26/1 Hosur road, Bommanahalli

Bangalore 560068, INDIA

Tel: +91 80 67027066

Fax: +91 80 67027004

Email: [email protected]

Web: www.rollonindia.in