Increasing demand of Fluorosilicone

Fluorosilicone rubber contains trifluoropropyl groups that enhance its chemical resistance to non-polar solvents, fuels, oils, acids, and alkaline chemicals

Polymer Technologist

Ami Polymer Pvt. Ltd.

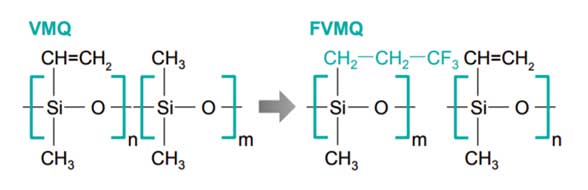

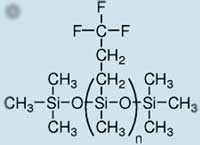

Fluorosilicone rubber is called as modified version of silicone rubber which has been fluorinated to finish up the polymer chains so that its chemical resistance is improved. fluorosilicone is also known as FVMQ (fluorovinylmethylsiloxane). It can be processed by compression molding, calendaring, extrusion, and liquid injection molding. Fluorosilicone rubber displays a working range between -60°C and +225°C. Fluorosilicone rubber is formulated from fluorosilicone polymers that contain a (-Si-O-) repeating group on the polymer backbone. One unique difference, compared to their dimethylsiloxane counterparts, is the incorporation of a fluorine component attached to the polymer backbone. Fluorosilicone polymers replace one (methyl) side group on each silicon with a (trifluoropropyl) side group.

Structure

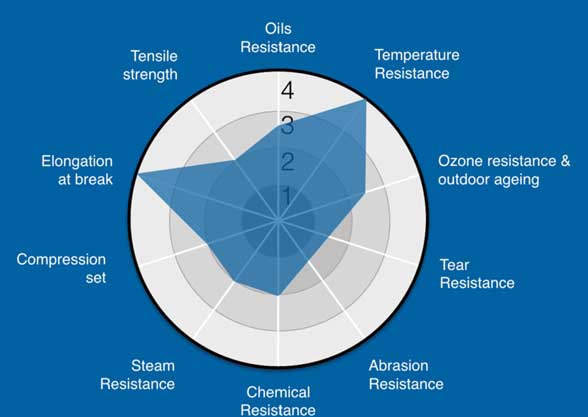

Fluorosilicone rubber contains trifluoropropyl groups that enhance its chemical resistance to non-polar solvents, fuels, oils, acids, and alkaline chemicals. And also a flame retradance. The unique properties of fluorosilicone make it a problem-solving material

Why FSR is in demand

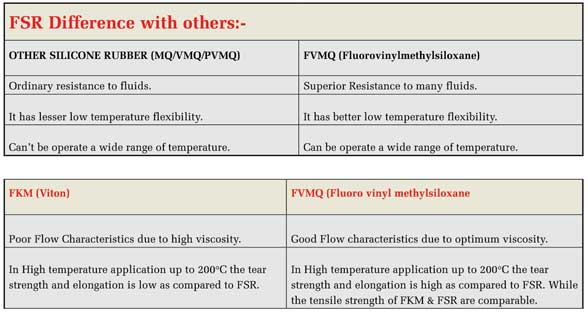

It is easy to understand with the difference.

FSR can be blended with other silicones to obtain a fluid resistance that is intermediate between the two polymer types. Since FSR has a significantly higher cost than other silicones. Due to the extremely polar fluorine element in the chemical structure of FSR, FSR shows superior resistance to many fluids.

Area of Demand (Applications):-

The increasing use of Fluorosilicone rubber in the pharmaceutical industry for fluid transfer, peristaltic pumping and filling operations. FluoroSilicones are UV stable, thermally and chemically stable. Its Resistance to bacteria, ease of sterilization, and non-reactive with the body and other materials means that silicone is the material of choice for medical applications and infant care products. That widely used in industrial, aerospace, automotive and aviation applications for static sealing and cushioning.

It is also used in:-

- Fuel line quick-connect seals

- Electrical connector inserts

- Air pump valves

- Exhaust gas recirculating diaphragms

- Turbocharger hose liners

- Fuel-resistant hydraulic and electrical clamp blocks

- Vapor recovery management system seals

- Natural vacuum leak detection control diaphragms

- Engine gaskets

- Fuel line pulsated seals

- Brake vacuum units.

For more information

Ami Polymer Pvt. Ltd.

https://www.amipolymer.com/