Indian economy will witness a robust growth in the coming years and KSB will focus on a profitable growth strategy

KSB India is a formidable name in the pumps Industry and Valve Industry. Armed with seven manufacturing facilities, four zonal offices, 16 branch offices, six service stations, close to 2000 employees and a nation-wide network of dealers, the company is eminently placed to deliver world-class products, systems and solutions to its customers across India. KSB has a complete basket of products for all applications including the most critical ones in energy and nuclear sectors. The USP of its products is the reliable German design and cutting-edge German technology, says Farrokh Bathena, Director-Sales & Marketing, KSB India in an interview with P.K. Balasubbramaniian. Excerpts:

Q. KSB India has been around for over six decades witnessing and contributing to the growth of industrial India. Could you give an overview of your journey so far?

KSB Limited was founded in India in the year 1960 at Pimpri, Pune in the state of Maharashtra. To cater to the needs of the new and emerging India, KSB India has invested in world-class facilities and technologies. Our manufacturing facilities in India are fully equipped to meet customers’ expectations right from the design, testing, manufacturing, and quality assurance on all aspects of fluid mechanics.

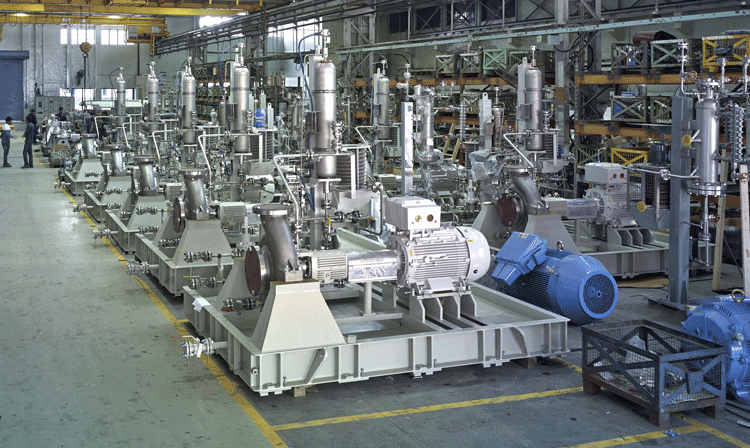

Today, KSB in India operates through its seven own manufacturing facilities, four Zonal offices, 16 branch offices, and six service stations. The factories are situated at Pimpri, Chinchwad, Shirwal (Khandala), Vambori, Sinnar, Coimbatore, and Aluva (Cochin). Our state-of-the-art manufacturing plants ensure that products of the highest quality are delivered to our customers.

While the zonal sales offices are located in Noida, Kolkata, Mumbai and Chennai, the service stations are located in Noida, Howrah, Odhav, Chennai, Chinchwad, and Baddi. We have close to 2000 employees who work relentlessly to ensure quality production, excellent customer support and service. In addition, we have a family of 1,000+ authorized dealers and more than 325 Authorized Service Centers all across the country which facilitates in bringing our products to the doorstep of the Customer. KSB with its global network also makes it easier for us to reach all our international Customers.

Q. You are a leader in fluid flow technology. What’s your broad product spectrum?

KSB specializes in Centrifugal End Suction Pumps, High-Pressure Multistage Pumps, Pumps for Nuclear Applications, Industrial Gate, Globe, Check Valves, Submersible Motor Pumps, monobloc & mini monobloc pumps, Hydro pneumatic Systems and Control valves. So, when it comes to pumps and valves, you name it and we have it. Our strength lies in offering a complete product basket for all applications and bringing the latest technology to the Indian market. The USP of our products is the Reliable German Design, German Technology, proven hydraulics, and the large number of pumps that are still in operation due to our presence of more than 60 years in India.

KSB with its wide product portfolio serves all the six market segments like Oil & Gas, Energy, Water & Waste Water, General Industry, Building Services, and Mining. KSB not only engineers state-of-the-art pump and valve technology but also strives to provide an air-tight array of services around pumps and valves.

Q. When we talk of KSB, the image that conjures up is that of a high-tech manufacturer of pumps and valves who can offer cutting-edge solutions for most critical applications. How do you substantiate this?

Yes, you are right. KSB is proud to be at the forefront of providing innovative solutions and the latest technology for various pump applications. KSB was the first pump company to indigenously develop and supply the Boiler Feed Pumps for supercritical power plants in India. Other specialized products which KSB has introduced include the Absorber Recirculation Pumps (KWPK), the recent Indigenous development of Main Feed Water Pump (RHD-350) and Booster Pump (BP) as well as YNK 350-620 pumps for Nuclear applications. KSB has also been a pioneer in supplying pumps for the Primary cycle of Nuclear power plants.

Q. Could you take us through some of the path-breaking innovations you have showcased recently?

Yes, of course. KSB has innovated various smart services which enables the customers to efficiently use our products with the latest automation and intelligent services developed in-house. The focus has been on Product Innovation and bringing out products that cater to a much wider demand at an optimal cost.

First is KSB Guard, a cloud-based monitoring solution for standard pumps, is a digitalisation project initiated by KSB’s Innovation Lab which enables digitalised recording of pumps’ performance and status parameters. It monitors all connected pumps in parallel and immediately notifies irregularities and allows to maintain an overview of pumps’ data at all times without having to be physically on-site.

Another product we would like to highlight is KSB moviBOOST, a fully automatic intelligent water pressure boosting systems, equipped with KSB’s own controller, pump, motor, drives and valves and user-friendly touch screen interface which makes life comfortable with uninterrupted water supply to commercial and residential buildings.

When it comes to energy efficiency, KSB SuPremE® Ultra high efficiency motor (IE5)is what you can rely on. It is the world’s most efficient magnet-less motor. These IE5 motors not only have eco-balance by achieving considerable energy savings, but also contribute to a healthier environment as the motors incorporate zero magnetic materials made from rare earths.

KSB FlowManager is another KSB app that makes operating your pumps easier. It gives you an overview of the all-important parameters and information relating to your pump – directly on your mobile device. Thanks to direct settings options, it also gives you complete control.

KSB PumpMeter is another innovative product which enables comprehensive pump monitoring. At a glance, operators can see whether their pumps are at risk and if they are operating economically.

KSB PumpDrive is the latest generation of KSB’s variable speed drives. It ensures demand-driven pump operation and thus maximizes energy savings.

KSB MyFlow is another unique drive solution for constant flow applications that reduces variant complexity and makes planning more reliable as the operating point can be adjusted to individual requirements.

Q. How would you portray your strengths, capabilities and wherewithal?

Our state-of-the-art Pumps and Valves, besides having to move and manage water, also handle virtually every type of fluid of various temperatures and composition day in and day out. It is this inherent capability that has made our pumps and valves most reliable not only for the Water and Waste Water sector but also in Process plants, Building Services, Power stations and Oil and Refinery sectors. We are therefore often called upon for holistic solutions which include the development of complete plant systems from concept to commissioning.

Power generation needs to be at maximum efficiency and minimum environmental impact. This is where our Pumps and Valves play a key role like the KSB proprietary wear-ring design, which reduces internal leakages, extends pump life, and increases entire operations reliability. Likewise, our valves made from high creep resistant material withstand a temperature of up to 600 °C and pressure over 400 bar. It is for this reason our pumps and valves are often chosen in the majority of the power plants.

Our customer service knows no boundary. Our highly trained specialists will do the best they can to keep your installations running day-in and day-out.

Our close association with our customers helps our Research & Development center in India to constantly innovate to ensure that our products last longer, come with lower maintenance and energy needs, greater reliability and user-friendliness and minimize environmental impact.

Q. What’s your contribution to the energy sector?

As I told earlier, we can proudly say that our Absorber Recirculation Pumps (KWPK), the recent Indigenous development of Main Feed Water Pump (RHD-350) & Booster Pump (BP) (YNK 350-620) pumps for Nuclear applications and Boiler Feed pumps for Supercritical power plants are our most notable contributions to the

Indian Energy sector. KSB has also been a pioneer in supplying pumps for the Primary cycle of Nuclear power plants.

Q. Do you also offer customized solutions for nuclear applications?

Indeed, all the products which KSB supplies for the primary cycle of Nuclear power plants are customized to meet the specific applications. KSB Limited has been associated with the Department of Atomic Energy (DAE), India since 1970 to take up the challenges of indigenization of the pumps for Nuclear applications including primary coolant pumps, shut down cooling pumps, primary pressurizing pumps, emergency core-cooling pumps, etc.

Q. What are your capabilities in slurry handling and its recirculation?

KSB Group has more than 40 years of experience in the development of pumps and valves for slurry applications in Flue Gas Desulphurization (FGD) projects and Mining applications. KSB is also one of the market leaders for pumps required in Absorber Recirculation Pumps required in the FGD plants.

Q. Among the lot, would you like to talk about one recent ground-breaking achievement of your R & D?

Our R&D activities are conducted by our parent company in Germany and the products are manufactured under license by KSB Ltd. These initiatives have led to the manufacturing of high efficiency and high-reliability pump sets for the FGD application for the Supercritical power plants and the Nuclear pumps market. KSB has a design center located in Pune, Maharashtra called KSB Tech, which provides design support.

Recently, we inaugurated our first-ever Innovation lab at Nashik in order to further strengthen our position in the market as the aggressive player who believes in innovation and strives towards creating more value for our customers.

Q. What are the challenges ahead for you, and what efforts do you make to maintain your leadership position?

We feel the rising commodity prices shall pose a big challenge to all industries for maintaining their margin levels. Industries will be forced to pass on this increase in the market which eventually can affect the demand.

We are one of the dominant players in the market, and hold different market shares in the different segments in which we operate. Due to the multi-segment presence, KSB is not much affected by any individual market slowdown.

To further maintain our leadership position, we have undertaken various measures like improving product basket with the introduction of new products, bringing more focus to the sectors like Agriculture, Solar, Chemicals, Water and Waste Water, Pharma and other Life Science applications and digitalization initiatives. We feel this shall help to improve our position in the various markets in which we are present.

We are working closely on the development of Solar DC pumps since last few years. KSB aims to become a complete player in the solar segment in both AC & DC applications and may even eye for the role of a system integrator. With this initiative, we expect to grow our presence in the Solar pumps market many fold in the coming years.

There is increased focus in the Oil and Gas business for Valves, with the new latest qualification for Oil & Gas (ISO 16848-1, API RP591, API 600 13th edition) that we have received. Apart from this, we have introduced new products like Butterfly valves, Dual plate check valves etc to boost our product basket for valves.

Q. What are the prospects of the pump industry in the wake of GOI’s recent policy announcements and the impetus being given to the infrastructural development?

Elaborating the PM GatiShakti, under the recently announced budget for 2022-23, the Finance Minister has said that it is a transformative approach for economic growth and sustainable development & allocated Rs. 20,000 crore under this initiative. The approach is driven by seven engines, namely, Roads, Railways, Airports, Ports, Mass Transport, Waterways, & Logistics Infrastructure. All seven engines will pull forward the economy in unison. These engines are supported by the complementary roles of Energy Transmission, IT Communication, Bulk Water & Sewerage, & Social Infrastructure.

An allocation of Rs 60,000 crore to cover 3.8 crore households in 2022-23 for Har Ghar, Nal Se Jal and Rs 48,000 crore for the PM Awas Yojana will definitely boost the economy. The decision of levying additional excise of Rs. 2/litre for unblended fuel to promote ethanol distilleries is also of the highlight that we are eyeing as opportunities.

Owing to the above initiatives, KSB expects good business opportunities in the Energy sector, General Industry, Building segment, Water transport & Sewerage segment, and the Agriculture segment in the near future.

Q. What’s the way forward for KSB and where will you be five years hence?

We believe that the Indian economy will grow robustly in the mid-term.To maximize our share in this growth, we are continuing to invest in new products, increase the manufacturing capacity, enhance the skills of the employees with learning and development as well as in Digitalisation. With measures on a drive for innovation, additions to product basket, a complete digitisation to improve our operational efficiency, market entry into new segments, KSB continues to focus on a profitable growth Strategy. After Market area also looks positive as production ramping up will call for scheduled maintenance of equipment.

The company is focusing upon taking conscious efforts to increase its ESG score. Like every year we target to eye a double-digit growth y-o-y in line with CAGR. We have an ambitious growth plan and with current opportunities in the market, we really see it happening.