MDR – Internally motorized conveyor roller changes the whole landscape in material handling solution

A warehouse optimized for maximum efficiency isn’t always optimized for minimal energy use, but a veteran rollers manufacturer has a solution.

Founded in 1946 as a specialized maker of motors for fans and Vaccum Cleaners, ITOH DENKI became a pioneer in the industry when its founder invented the Motorized Driven Roller (MDR). By incorporating the motor and gearbox inside the e roller tube, the company was launched into the intralogistics industry by enabling the entire production from A to Z inhouse. United State Post Office chose to adopt this new roller technology, and then ITOH DENKI’s future as a major player was sealed when it introduced brushless 24V technology to conveyor systems. And it is now the first choice for Intralogistics & Automation Industry with 78 years of experience and 50% global market share.

Founded in 1946 as a specialized maker of motors for fans and Vaccum Cleaners, ITOH DENKI became a pioneer in the industry when its founder invented the Motorized Driven Roller (MDR). By incorporating the motor and gearbox inside the e roller tube, the company was launched into the intralogistics industry by enabling the entire production from A to Z inhouse. United State Post Office chose to adopt this new roller technology, and then ITOH DENKI’s future as a major player was sealed when it introduced brushless 24V technology to conveyor systems. And it is now the first choice for Intralogistics & Automation Industry with 78 years of experience and 50% global market share.

ITOH DENKI`s DNA is deeply rooted in Japanese “monozukui” or product making culture, which refers, always working towards a better quality at every level and enhancing the strength, which stems from the unique features of motorized driven roller technology-based material handling.

The MDR has just enough torque that, if you want, you can stop one roller with your hand and its biggest advantage is that you can make each conveyor section independent. In the past, an entire conveyor line was constantly powered to move just one small part, which was a waste of energy. Now it enables motors to run only when necessary, saving up to 60% in electric consumption.

The MDR has just enough torque that, if you want, you can stop one roller with your hand and its biggest advantage is that you can make each conveyor section independent. In the past, an entire conveyor line was constantly powered to move just one small part, which was a waste of energy. Now it enables motors to run only when necessary, saving up to 60% in electric consumption.

The majority of sales are to businesses handling small parts (up to 50kg) in plastic totes or carton boxes, Itoh DenkI also produces a roller with a larger diameter, making it attractive to the automotive sector as it can convey parts weighing up to 500kg as well as pallets weighing up to a ton.

ITOH DENKI is not only roller manufacturer but also a complete solution provider for scalable sorters with MDR based divert modules providing agility and ergonomics.

F-RAT-NX75 is uniquely able to transfer products at 90° on either side without lifting the product, ensuring smoother transfers and simpler conveyor design. This module is flexible in size which make it fit in every conveyor size with throughput of 2,250cs/hrs maximum. This product is TUV Rheinland certified, which defines the safety, efficiency, and quality. It can smoothly transfer and divert the goods below 50kg without any impact on the goods. ITOH DENKI offers you with a “complete product” which minimizes the installation time and minimize the downtime which is essential for all the end users who cannot waste lot of time on maintenance.

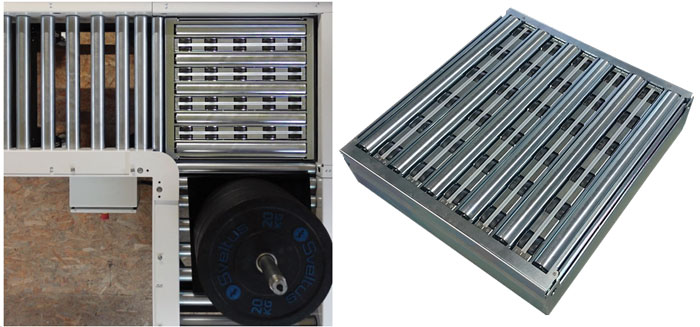

M-RAT, a highly innovative new diverter and sorter module, developed in response to burgeoning demands from customers globally for systems which can cope with heavier products, especially in manufacturing or on assembly lines. Drawing on a similar acclaimed 24V DC powered design which form the heart of the company’s F-RAT compact 90° diverter and sorter module for the precise transferring of smaller loads, M-RAT can handle individual loads of up to 250kg. This provides greater flexibility for designers needing to move heavier loads who have previously had to rely on bulky external motors or pneumatically powered systems which bring very specific challenges around commissioning, maintenance and safety.

Multi-Angle Ball Sorter (MABS ) boasts patented rotating ball transfer technology, which allows products to be diverted at any angle on both the left and right. It can achieve the through put 4,300 cs/hrs of up to 30kg in weight and is suitable for integration into any type of conveyor system. It is powered solely by 24V DC technology, optimizing safety when compared with pneumatically powered systems.

Available in total five sizes, MABS can be easily reconfigured to suit the requirements of changing set-ups, with up to eight units able to operate in tandem where larger transfer zones are needed. MABS’ high throughput, versatility and low profile design makes it ideal for a vast range of warehousing, e-commerce and intralogistics applications.

The POP-UP diverter module offers high-capacity lateral transfers at either 30° or 45° with a compact cassette design and 24 V, it can be easily fitted into most conveyor frames, in new or refurbished roller conveyors and can be used in a variety of applications for routing, sorting or mergings for a great variety of loads. The POP-UP is available in different sizes, for either 30° or 45° transfers, left or right.

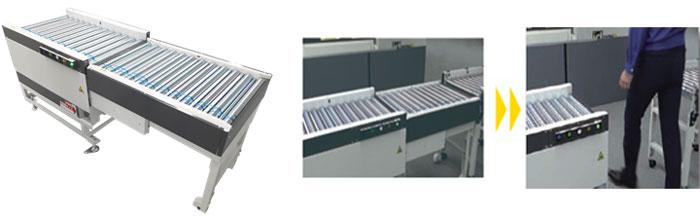

The Slide Open Gate (SOG) eliminates the culture of lifting up heavy conveyor gate which could invite human injuries and provides the gap in between the conveyor lines to pass through mainly for maintenance access. It allows the access to the conveyor line with a push of button and the most important thing is that it is completely non-pneumatic and operated with MDR, ITOH DENKI core product. It can carry the load below 30kg. SOG will also be provided a “complete product” by ITOH DENKI so that the OEM and conveyor manufactures need not to spend enormous amount of time in its design, engineering and assembly.