Shape of Things to Come in Linear Motion & Automation

“The next decade is going to be transformative for the linear motion and automation industry. We’re seeing an unprecedented convergence of technology, manufacturing expansion, and demand for precision,” says Superslides, in an interview. Excerpts:

Q What are the innovative products you are displaying at ENGIMACH-25, and what will be the centre of attraction in your pavilion?

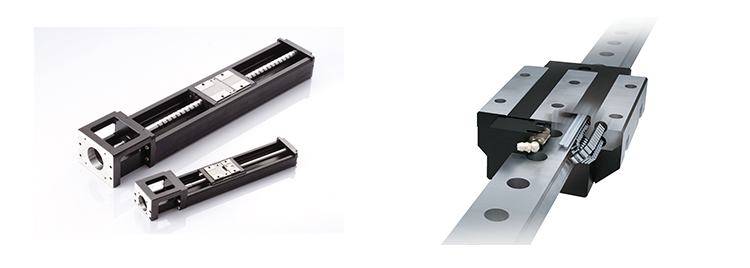

At ENGIMACH-25, we are showcasing the next generation of linear motion solutions designed for high-speed, high-accuracy, and maintenance-efficient applications. Our pavilion features advanced linear guideway systems, precision Ballscrews, rack and pinions, precision planetary gearboxes, precision lock nuts, compact motion modules, and turnkey linear stages designed for machine builders looking to scale automation.

Q What makes you the numero uno in linear motion systems?

What sets us apart is our ability to combine global-standard engineering with a deep understanding of Indian machine-building needs. We don’t just supply linear motion components—we provide end-to-end motion engineering.

Our leadership comes from:

Our leadership comes from:

• Extensive inventory and quickest delivery cycles, critical for India’s fast-paced manufacturing demands.

• Expert application engineering, ensuring customers get the right motion system for their load, accuracy, and life expectations.

• Strong partnerships with globally trusted brands, giving customers reliability at the right value.

• A pan-India support network, ensuring zero downtime through fast service and replacement availability.

This combination of performance, service, and industry knowledge is what truly makes us the first choice for machine builders across India.

Q What are the major growth drivers in the linear motion and automation industry over the next 5–10 years?

The next decade is going to be transformative for the linear motion and automation industry. We’re seeing an unprecedented convergence of technology, manufacturing expansion, and demand for precision.

The biggest growth drivers will be:

The biggest growth drivers will be:

a) Acceleration of Industry 4.0 & Smart Factories:

Indian manufacturers are rapidly moving toward digitalized, data-driven production. As machines become smarter and more connected, demand for high-precision linear motion systems—capable of repeatability, rigidity, and real-time monitoring—will rise significantly.

b) Expansion of EV, Electronics & Semiconductor Manufacturing:

These sectors require extreme precision, cleanroom compatibility, and high-speed automation. Linear guides, ballscrews, and actuators become the backbone of assembly, dispensing, battery production, and inspection lines.

c) Rapid Automation Adoption by MSMEs:

As labor costs rise and productivity becomes a competitive differentiator, small and mid-size manufacturers are automating like never before. This shift creates massive demand for cost-effective yet reliable linear motion solutions.

d) Government Initiatives—Make in India, PLI & Infrastructure Growth:

These schemes are encouraging large-scale investments in machine building, robotics, packaging, logistics automation, and CNC manufacturing—directly boosting the linear motion ecosystem.

e) Shift Toward High-Speed, Compact Machinery:

Industries are demanding machines that are faster, lighter, and more energy-efficient. This drives the need for advanced linear motion systems with reduced friction, higher load capacities, and longer life cycles.

f) Robotics & Collaborative Automation:Cobots, AGVs, and precision robotic systems rely heavily on linear modules and guided motion. As robotics becomes mainstream, linear motion demand grows exponentially.

Overall, the coming decade will be defined by precision, speed, digitalization, and reliability. Linear motion systems will play a central role in enabling India’s manufacturing leap, and companies that combine engineering excellence with strong customer support will lead this transformation.

Q What are your bespoke offerings to Indian industry that have set high benchmarks for quality and precision in today’s competitive environment?

Q What are your bespoke offerings to Indian industry that have set high benchmarks for quality and precision in today’s competitive environment?

Our bespoke offerings are designed around one principle—precision without compromise. Every solution we deliver is engineered to match the specific performance, cost, and lifecycle demands of Indian OEMs.

Key differentiators include:

Key differentiators include:

• High Speed linear motion assemblies built to suit higher rpm, vibrations, and high-duty cycles.

• Tailor-made motion modules and actuator systems that reduce machine build time and increase repeatability.

• Application-specific recommendations, from heavy-duty automation lines to delicate precision machinery.

• Quality assurance through stringent testing, ensuring every system meets global tolerance, preload, and rigidity standards.

By offering engineered-to-fit solutions rather than generic components, we help machine builders achieve higher accuracy, greater uptime, and faster production—setting new benchmarks for modern Indian manufacturing.