Welding & The Automobile Sector

The Automotive Industry is one of the largest in India and accounts for 7.1 per cent of the Indian GDP. At around USD 93 billion. It amounts to approx. 30% of the turnover of the manufacturing sector and is a very important component of India’s growth story. India manufactured more than 25 million automobiles in FY17 and is a prominent auto exporter with strong export growth expectations for the near future.

Around Rs.47,000 crores have been pumped into the auto industry in the last one year alone and that is nearly a third of the current Indian automotive market. Car makers, both domestic and foreign, have lined up investments to a tune of almost $10 billion or nearly Rs. 60,000 crores over the next few years.

Several initiatives by the Government of India and the major automobile players in the Indian market are expected to make India a leader in the two and four-wheeler market in the world by 2020.

The Government plans to promote eco-friendly cars in the country i.e. CNG based vehicle, hybrid vehicle, and electric vehicle and made mandatory of 5 per cent ethanol blending in petrol.

Welding Automation

Reductions in the workforce over the last several years have left the industry with fewer employees to monitor welding operations and the overall shortage of skilled welders has compounded the challenge. Whereas 10 years ago a large automotive supplier may have had one welding technician for 20 robots, today that ratio has increased to as few as one welding technician for every 50 robots – or more.

The most commonly used welding methods for automotive applications are resistance spot welding, resistance seam welding, metal inert gas (GMAW) welding, tungsten inert gas (GTAW) welding as also laser beam welding (LBW), friction welding (FW), and plasma arc welding (PAW).

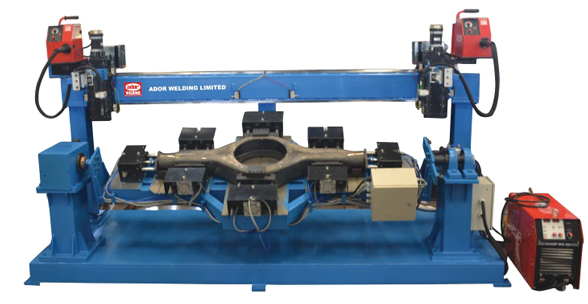

Ador Welding Offers a plethora of solutions through a wide range of Welding consumables, Welding equipment, Welding Automation, Plasma and Gas CNC based cutting systems encompassing most of these processes:

Auto-Exhaust Applications

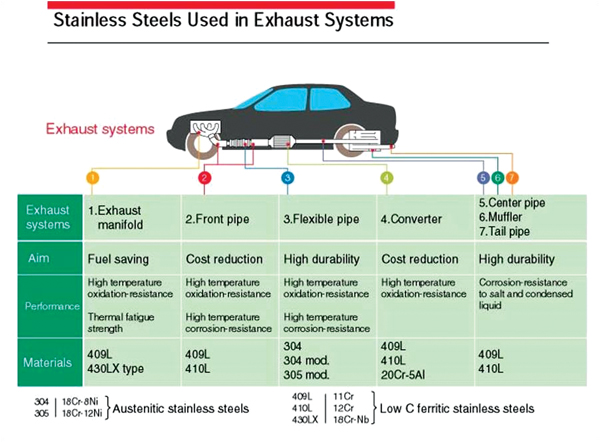

The use of stainless steels in automobiles started when automobiles came to be equipped with 3-way catalytic converters to meet intensifying regulations over exhaust gas emissions. The requirement to have longer service life accelerated the switchover from hot dip aluminized carbon steel to stainless steel in this application. Today, stainless steel is used in almost all exhaust system parts from the cylinder head gasket to the tail pipe. The consumption of stainless steel in the exhaust system per passenger car varies from model to model but averages about 15kg per car. The stainless-steel consumption is expected to increase in the exhaust system of diesel-powered automobiles, mainly trucks, to meet the growing social demand for stricter exhaust gas emission regulations.

Stabilized ferritic stainless steels represent the best cost / benefit solution for exhaust system components: it gives designers optimal combinations that work both in elevated temperatures and complex corrosive environments.

The exhaust system components are manifold, close coupled and underbody catalytic converters, flexible bellow, muffler, resonator, connecting pipes, flanges, and tailpipe. The part of the exhaust system containing the manifold, converter and the flex joint is named as hot end since this part of the system is relatively hot due to the hot exhaust gas passing through these components. The part consists of intermediate pipe, resonator and the muffler is named as cold end since the gas tends to cool down from the exit of the flex tube. The temperature of the hot end of the gasoline operated vehicle can be as high as 1050°C while the highest temperature of the cold end is about 650°C.

There are benefits of Nb regarding oxidation resistance at high temperatures.

It has been demonstrated that Nb containing ferritic grades have better high temperature performance when compared to Ti single-stabilized or austenitic grades.

This is because Nb forms a thin, homogeneous and adherent oxide layer in the surface of the steel, avoiding spalling and re-oxidation of the material during the exhaust system thermal cycling (the typical on/off operation of the car’s engine). It also results in lower loss of material which can be translated into higher life cycles of the component, meaning a longer life, reduced frequency of replacement and long term cost savings.

Study on metal loss of different stainless steels at 950°C shows that with increase in Nb content, higher temperature oxidation resistance improves as Nb forms less porous and more adherent oxides which results in less spalling and less re-oxidation.

ADOR offers comprehensive solutions for Automotive applications:

- Solid wire for GMAW welding:

- Non-copper coated Mig wire – Automig70S6 N:

- Non-copper coated (Copper free) Mig wire. Gives excellent welding characteristics.

- Better welding speed.

- Lower spatter.

Miginox 430L Nb:

- Superior wire of unique chemistry stabilized with Nb.

- Minimizes the consumption of nozzles and avoids the excess of projections during welding.

- Best welding performance with shielding gases 98Ar+2O2 and 1-5CO2 mixed with Ar.

Autoweld 400:

- Ferritic Stainless Steel solid wire.

- High corrosion and heat resistance.

- Suitable for joining and cladding of typical 17% Cr steels.

- Best suited for ferritic martensitic chrome steels.

from ADOR

Metal cored wire: Metal cored wires offer higher productivity in terms of higher welding current densities and hence higher welding speeds. They give much higher range of welding parameters to weld without the danger of burn through. The above come with an additional advantage of better root gap bridging ability. The above point is best illustrated in the graph below.

Miginox MC 409:

- Ti stabilized metal cored wire that gives minimal / no slag.

- Operates at higher current densities.

- High deposition rate gives very good productivity.

Both the solid and metal cored wires are supplied in layer wound condition in plastic spools with 12.5 / 15 kg wire per spool.

ADOR evolves continually to meet the latest needs of the industry in its relentless pursuit of excellence.

— Article by

Aniruddha R. Vilekar, Head-Marketing, Ador Welding Ltd.