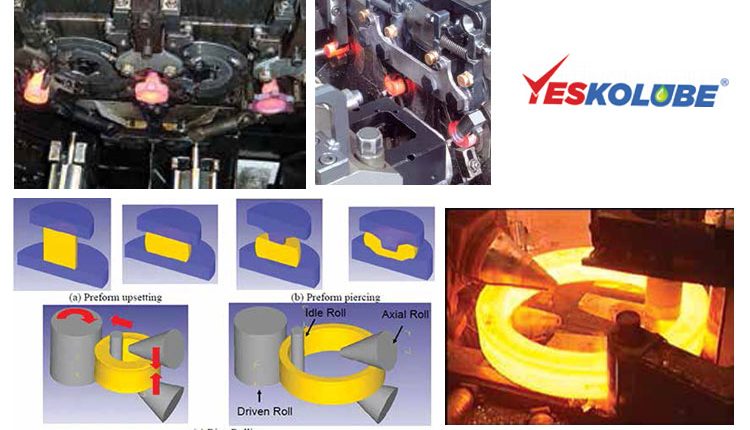

What is Seamless Rolled Ring Forging Process?

- Ingot or billet is cut to size then upset to achieve mechanical properties

- Punching & piercing to create ring rolling donut

- Ring Rolling process begins with ID & OD pressure applied to donut

- Ring diameter increases as pressure applied to ID & OD increases. Axial roll controls height

- When desired size is achieved, process is complete

Recirculating water & waste oil or furnace oil are generally used for die cooling & lubrication purpose which makes working environment dirty & hazardous smoky.

Yeskolube India Pvt.Ltd. manufacturer of different kind of forging die lubricants having a perfect solution for Ring Rolling Forging applications. Along with these lubricants Yeskolube manufacturers Super High Performance Non-Graphite Forging Lubricants Compatible For High Speed Multi-Station Forging Like Forging On Hatebur & Schuler Presses.

The super high performance specially formulated die lubricants are 100 % water soluble, contains no graphite & biodegradable.

Features of these lubricants are as below:

- Contains Excellent Lubrication Additives

- Provides Excellent Die Cooling Properties

- Stronger Film Formation

- Excellent Load Carrying Capacity

- 100% Smokeless Forging Application

Consistent use of these lubricants can have benefits like:

- Substantial Tool Life Improvement

- Clean & Smokeless Working Environment

- Can Reduce Manpower In Sizing Operation

Yeskolube India Pvt. Ltd. started with a singular goal – to make indigenous lubricants available to Indian manufacturers and industries that are on par with international standards. Yeskolube is the youngest, and one of the fastest-growing brand – in the world of forging and casting lubricants, becoming one of the prominent manufacturers within a very short span. Yeskolube has emerged as one of the rising stars of the lubrication industry, providing high-quality, best-in-class products at cost-effective prices.