The steel industry is one of the most demanding manufacturing sectors, characterized by extreme temperatures, heavy materials, and hazardous working environments. With the rising need for efficiency, quality, and worker safety, robotic automation is playing an increasingly crucial role in transforming steel production. From material handling to welding, inspection, and packaging, robotic systems are enhancing productivity while reducing operational costs and risks.

The Growing Role of Robotics in Steel Manufacturing

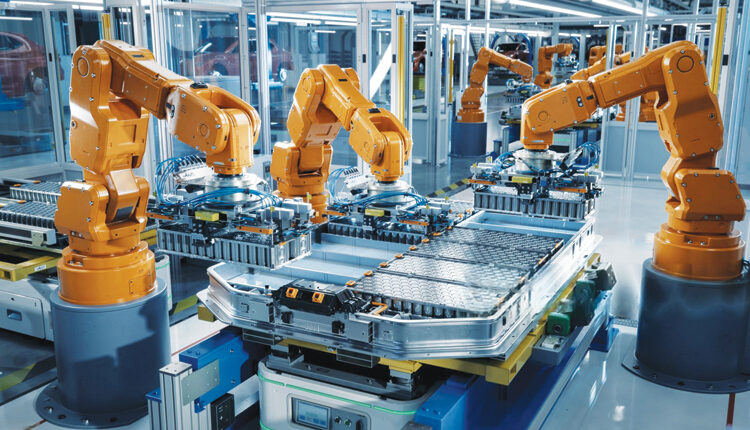

Automation has been a part of the steel industry for decades, but recent advancements in robotics, artificial intelligence (AI), and the Internet of Things (IoT) have taken it to new heights. Robots in steel manufacturing are designed to withstand high temperatures, harsh environments, and heavy loads, making them indispensable for a range of applications.

Material Handling and Transport

Steel manufacturing involves moving heavy raw materials, semi-finished products, and final components. Traditional handling methods involve significant labor and pose safety risks. Robotic systems equipped with advanced sensors and machine vision can automate material handling, reducing human intervention and minimizing errors. Automated guided vehicles (AGVs) and robotic arms ensure smooth transportation of steel slabs, billets, and coils, optimizing logistics within the plant.

Welding and Cutting

Welding is an integral part of steel fabrication, and robotic welding has revolutionized the process by improving precision, speed, and repeatability. Robotic welders are capable of performing spot welding, arc welding, and laser welding with minimal defects. Similarly, robotic cutting using plasma, laser, or waterjet technology ensures accurate and high-quality cuts, reducing material wastage.

Inspection and Quality Control

Ensuring the quality of steel products is essential to meet industry standards. Traditional inspection methods are labor-intensive and prone to human error. Robotic inspection systems use machine vision, thermal imaging, and AI-powered analytics to detect surface defects, dimensional inaccuracies, and internal flaws in steel components. These systems enhance quality assurance while significantly reducing inspection time.

Furnace Operations & Heat Treatment

Steel production involves high-temperature processes such as smelting, casting, and heat treatment. Robots are increasingly being deployed in furnace operations, where they handle hot metal and assist in loading and unloading heat treatment furnaces. By automating these processes, robots enhance worker safety and improve process consistency.

Maintenance and Repairs

Unplanned downtime in steel plants leads to significant financial losses. Robotic automation plays a critical role in predictive maintenance and repairs. Robots equipped with sensors and AI algorithms can monitor equipment conditions in real-time, detecting anomalies before they lead to breakdowns. Automated maintenance robots also perform routine cleaning, lubrication, and part replacements, ensuring continuous operations.

Packaging and Warehousing

Robotic automation extends to the final stages of steel manufacturing, including packaging and warehousing. Automated stacking, palletizing, and labeling systems streamline the packaging process, while robotic warehouse solutions optimize inventory management. These automated systems improve efficiency, reduce storage costs, and enable faster order fulfillment.

Benefits of Robotic Automation

The adoption of robotics in steel manufacturing offers numerous advantages:

- Increased Productivity:

Robots operate at high speeds with minimal downtime, ensuring continuous production and higher output. - Enhanced Safety:

Automation reduces human exposure to hazardous conditions, minimizing workplace injuries. - Improved Quality:

Robotic systems maintain precision and consistency, leading to superior product quality. - Cost Reduction:

By optimizing labor, minimizing material wastage, and reducing maintenance costs, robotics lower overall production expenses. - Sustainability:

Energy-efficient robotic systems contribute to reducing the carbon footprint of steel manufacturing processes.

Challenges and Future Outlook

Despite the numerous benefits, the implementation of robotic automation in the steel industry comes with challenges. High initial investment costs, the need for skilled personnel to operate and maintain robotic systems, and integration complexities can pose barriers to adoption. However, with advancements in AI, machine learning, and industrial IoT, these challenges are gradually being addressed.

The future of robotic automation in steel manufacturing looks promising. Emerging trends include collaborative robots (cobots) working alongside human operators, AI-driven autonomous decision-making systems, and the integration of digital twins for real-time process optimization. As technology continues to evolve, the steel industry will witness greater automation, leading to higher efficiency, safety, and competitiveness.

Conclusion

Robotic automation is revolutionizing the steel industry by streamlining operations, enhancing safety, and ensuring superior product quality. From material handling to welding, inspection, and maintenance, robots are playing a pivotal role in modern steel manufacturing. As technology advances and costs decrease, the adoption of robotics in the steel industry is expected to accelerate, shaping a more efficient and sustainable future for steel production.