In modern manufacturing and logistics, efficiency, precision, and consistency are the cornerstones of competitiveness. Industries across sectors — from automotive and electronics to food processing and pharmaceuticals — are under constant pressure to increase throughput, reduce costs, and ensure safety. At the heart of this evolution lies one of the most transformative integrations of mechanical and digital systems: conveyors and process automation. The synergy between these two has revolutionized material handling, enabling seamless, intelligent, and efficient production flows that define Industry 4.0.

The Role of Conveyors in Modern Industry

Conveyors have long been the lifeline of industrial operations. From simple belt conveyors that move boxes on an assembly line to sophisticated automated conveyor systems that handle thousands of items per hour, they represent the most fundamental means of material movement in factories, warehouses, and distribution centers.

The core idea remains the same — moving material from one point to another efficiently — but the technology has evolved dramatically.

Earlier, conveyors were largely mechanical, relying on belts, rollers, chains, or slats driven by motors. Today, they are highly intelligent, sensor-integrated systems that communicate with robotic arms, sorting systems, and warehouse management software. Conveyors are now capable of adjusting speeds, routing materials dynamically, and self-monitoring their performance for predictive maintenance.

The major types of conveyors used in industries include belt conveyors, roller conveyors, chain conveyors, screw conveyors, pneumatic conveyors, and overhead conveyors. Each serves specific purposes — belt conveyors for general goods movement, roller conveyors for heavy-duty industrial applications, chain conveyors for pallets and crates, and pneumatic systems for powders or granules.

Overhead conveyors, on the other hand, optimize floor space in automotive paint shops and garment industries. What unites all these systems is their contribution to efficient, uninterrupted flow within the production or logistics chain.

Evolution Toward Automation

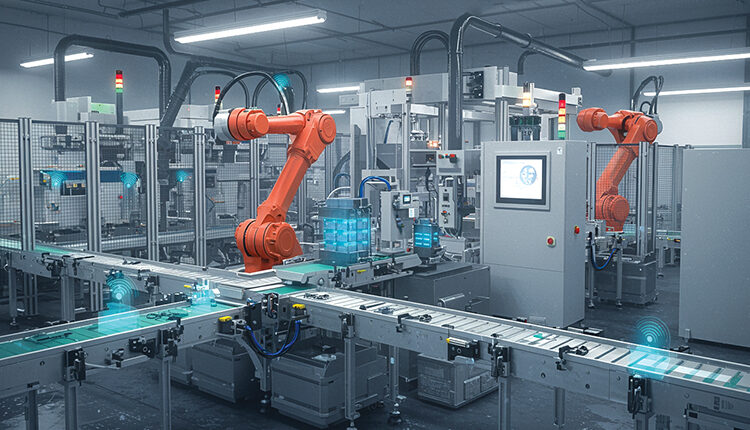

The turning point in the history of conveyors came with the rise of automation. The integration of sensors, programmable logic controllers (PLCs), robotics, and data systems transformed conveyors from passive carriers to active participants in intelligent manufacturing. This evolution aligns perfectly with the philosophy of process automation — the use of technology to execute repetitive or complex tasks with minimal human intervention, ensuring accuracy, speed, and reliability.

Automated conveyors now communicate with manufacturing execution systems (MES) and enterprise resource planning (ERP) systems. They can automatically reroute materials based on order priorities, detect jams or faults, and even trigger robotic operations such as sorting, packaging, or palletizing. The seamless flow of data between conveyors and automation systems ensures that each product or component is tracked, inspected, and delivered at the right place and time.

For instance, in automotive manufacturing, conveyors synchronize with robotic welding and painting cells to ensure just-in-time delivery of components. In e-commerce fulfillment centers, conveyors equipped with barcode or RFID scanners identify and sort thousands of packages every hour with minimal error. In food processing plants, conveyors integrated with vision systems and weighing sensors maintain quality and hygiene standards by rejecting defective products automatically.

Key Technologies Driving Integration

The convergence of conveyors and process automation is being accelerated by a series of cutting-edge technologies.

1 Sensors and IoT (Internet of Things):

Modern conveyors are embedded with sensors that measure speed, load, vibration, and temperature. These data points, when connected via IoT networks, allow real-time monitoring of system health and performance. Predictive maintenance becomes possible — identifying wear or imbalance before breakdowns occur.

2 Robotics:

Conveyors often act as the link between robotic stations. Collaborative robots (cobots) pick, place, or assemble items from conveyors, while vision-guided robots identify and handle objects of varying shapes and sizes. The conveyor’s movement is synchronized with the robot’s task cycle through precise communication protocols.

3 Artificial Intelligence (AI) and Machine Learning:

AI-driven control systems analyze data from conveyors to optimize routing, detect anomalies, and improve process efficiency. Machine learning algorithms can predict material flow patterns and adapt conveyor speeds dynamically, reducing bottlenecks and downtime.

4 Advanced Motion Control:

Servo-driven and variable frequency drives (VFDs) now enable smooth acceleration, deceleration, and synchronization of multiple conveyors. This ensures gentle handling of products, critical in industries like food, pharmaceuticals, and electronics.

5 Digital Twins and Simulation:

Before deployment, conveyor and automation systems are simulated digitally to predict throughput, energy consumption, and layout efficiency. The digital twin mirrors real-time operations, allowing engineers to test configurations virtually and enhance performance continuously.

Benefits of Conveyor-Based Automation

The integration of conveyors with process automation delivers a multitude of benefits across industries:

• Enhanced Productivity: Automated conveyors operate continuously, with minimal human intervention, enabling 24×7 operations and higher output.

• Consistency and Accuracy: With precise control over movement, timing, and routing, automation minimizes errors and ensures product uniformity.

• Reduced Labor Dependency: Automation relieves human operators from monotonous and physically demanding tasks, reducing fatigue and improving safety.

• Improved Safety: Automated conveyors are equipped with sensors and emergency stop systems that prevent accidents. Moreover, reduced human interaction with moving machinery lowers injury risks.

• Space Optimization: Overhead and modular conveyors enable better space utilization, freeing up valuable floor area for other processes.

• Scalability: Modular automated systems can be easily expanded or reconfigured to match changing production needs.

• Data-Driven Insights: Real-time data collected from conveyors helps track performance metrics like throughput, energy usage, and maintenance cycles.

Applications Across Industries

The impact of conveyors and process automation extends to almost every industrial sector.

• Automotive: Automated conveyors streamline assembly lines, synchronizing material flow with robotic operations for welding, painting, and inspection.

• Food & Beverage: Hygienic stainless-steel conveyors equipped with wash-down systems ensure sanitary handling of products. Automation maintains consistent flow through packaging, labeling, and palletizing.

• Pharmaceuticals: Precision conveyors handle delicate blister packs or vials under cleanroom conditions, maintaining traceability and compliance.

• E-commerce and Warehousing: High-speed conveyors and sortation systems powered by automation and AI manage thousands of SKUs efficiently, enabling same-day delivery.

• Mining and Cement: Heavy-duty conveyors transport bulk materials over long distances, with automated control ensuring balanced loads and reduced spillage.

• Electronics: Gentle handling conveyors integrated with vision inspection systems ensure quality and zero-defect manufacturing in PCB and semiconductor assembly lines.

The Human Element in Automated Systems

While automation reduces human intervention, it doesn’t eliminate the human element. Skilled operators and engineers are still crucial for programming, monitoring, and maintaining automated conveyor systems.

Training the workforce to work alongside automation — interpreting data, troubleshooting systems, and optimizing performance — is vital. In fact, the trend toward human-machine collaboration defines the next phase of industrial transformation.

Sustainability and Energy Efficiency

Modern conveyors are not just faster and smarter — they’re also greener. Energy-efficient drives, regenerative braking, and load-based control systems reduce power consumption. Automation minimizes waste by ensuring precise material handling and reducing product damage.

The use of recyclable materials in conveyor construction and predictive maintenance further contributes to sustainability goals.

The Road Ahead: Smart Factories and Beyond

As industries embrace Industry 4.0 and move toward Industry 5.0, conveyors and process automation will continue to play an even more significant role. The next generation of systems will be fully connected, adaptive, and autonomous, capable of learning and optimizing themselves without manual intervention. Integration with cyber-physical systems, AI-driven decision engines, and real-time analytics will make conveyor systems integral to smart factories.

In logistics, autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are already redefining material transport, working seamlessly with stationary conveyors. The hybridization of these systems will ensure total flexibility in material flow, eliminating bottlenecks and downtime.

Conclusion

Conveyors and process automation together represent the backbone of modern industrial efficiency. What began as a mechanical solution to move goods has evolved into a dynamic, intelligent, and data-driven system that powers the world’s most advanced factories and distribution centers.

The combination of mechanical precision and digital intelligence ensures that materials flow smoothly, processes remain synchronized, and production never stops.

As industries continue to innovate, the integration of conveyors and automation will remain the key driver of operational excellence, productivity, and sustainable growth in the manufacturing and logistics ecosystem.