What Makes These Hoses Industry-Ready

• Consistent purity: The platinum-curing process significantly reduces leachables, making the hoses well-suited for pharmaceutical media, bioprocess fluids, and food-grade transfers.

• Reinforced performance options: Polyester braiding and stainless-steel helical wire versions provide kink resistance and support demanding line conditions.

• Thermal and chemical reliability: Suitable for autoclave cycles, CIP/SIP environments, and exposure to a broad range of processing chemicals.

• Process visibility: Transparent options allow operators to visually monitor flow and detect air pockets or particulate presence.

• Traceability and documentation: Each batch carries clear identification and is backed by compliance documents essential for audit-ready facilities.

Application Areas

• Fluid transfer in pharmaceutical and biotech manufacturing

• Peristaltic pump systems requiring stable flow under repeated compression

• Dairy and food processing lines where hygiene and flavour neutrality matter

• Chemical and industrial systems that demand heat resistance and consistent performance

• High-vacuum printing, coating, and processing equipment

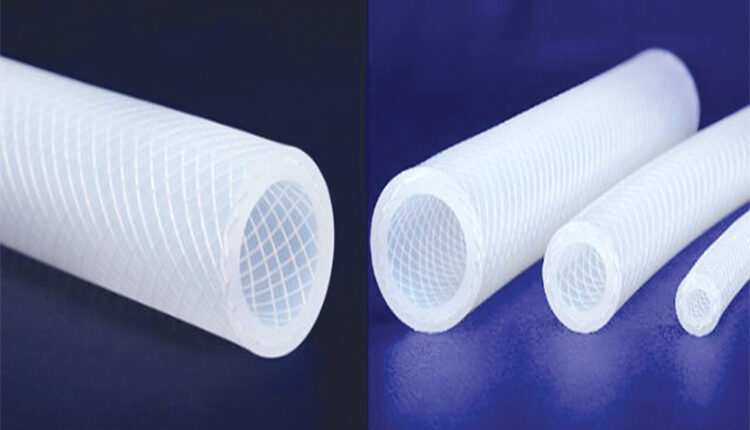

1 Imafit® – Polyester-Braided Platinum-Cured Silicone Hose

Constructed from platinum-cured silicone with a polyester braid reinforcement.

Flexible yet durable under pressure, with low extractables—ideal for hygienic environments.

Applications: Fluid transfer in pharmaceutical and biotech manufacturing, food-grade media delivery.

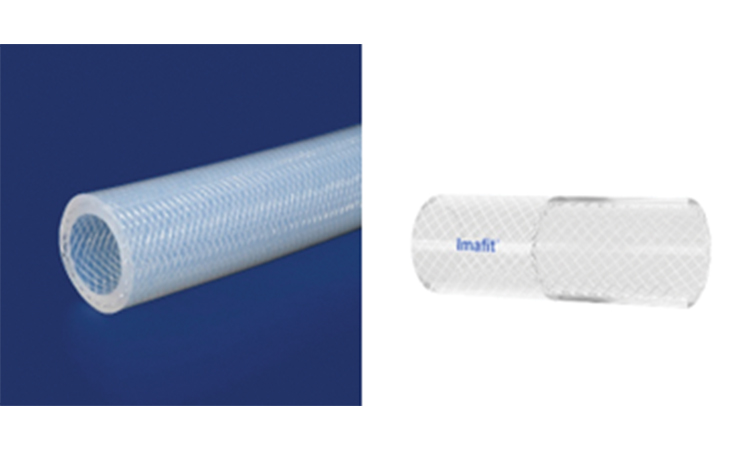

2. Imavac® – SS 316L Helical Wire Reinforced Silicone Hose

2. Imavac® – SS 316L Helical Wire Reinforced Silicone Hose

Platinum-cured silicone reinforced with stainless-steel 316L helical wire for vacuum and pressure performance.

Kink-resistant, reliable under high vacuum or suction conditions.

Applications: Vacuum transfer lines, suction systems in reactor feed or pharma equipment.

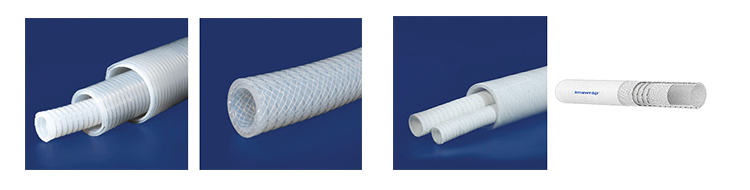

3. Imawrap® – Fabric & Wire Reinforced Silicone Hose

Silicone hose reinforced with multiple plies of polyester fabric plus SS helical wire—designed for heavy duty and semi-liquid transport. Robust for challenging routing and media types.

Choosing the Right Hose Variant for Your Operation

Choosing the Right Hose Variant for Your Operation

• When selecting from these brands, consider:

• Required pressure or vacuum rating

• Sterilisation compatibility (autoclave, gamma, ETO)

• Flexibility and bend radius requirements

• Bore size and flow-rate demands

• Need for reinforcement or chemical compatibility

• Documentation, traceability and regulatory compliance