The electrical sector is undergoing a significant transformation, driven by automation and digital technologies. Automation is playing a critical role in enhancing efficiency, safety, and reliability while reducing operational costs. With advancements in artificial intelligence (AI), machine learning (ML), Industrial Internet of Things (IIoT), and smart grids, the industry is shifting towards a more intelligent and interconnected infrastructure.

The Role of Automation in the Electrical Industry

Automation has revolutionized various aspects of the electrical sector, from power generation and transmission to distribution and consumption. Smart systems are now capable of predictive maintenance, remote monitoring, and real-time data analysis, enabling seamless operations and reduced downtime. The integration of automation in the sector ensures better energy management, minimizes human intervention in hazardous environments, and optimizes resource utilization.

Smart Grids: The Backbone of Electrical Automation

One of the most significant advancements in the electrical sector is the development of smart grids. Unlike traditional grids, which operate on a one-way transmission model, smart grids use automation and communication technologies to enable two-way interaction between energy providers and consumers. These grids incorporate AI-driven analytics, sensors, and IoT devices to monitor energy demand and supply in real-time, ensuring efficient power distribution and minimizing outages.

Smart grids facilitate demand response programs, where energy usage can be optimized based on real-time consumption patterns. Additionally, they integrate renewable energy sources such as solar and wind, enhancing sustainability and reducing dependency on fossil fuels. The automation of grid management allows utilities to detect and rectify faults promptly, thereby improving service reliability.

![Electrical Sector]() Automation in Power Generation

Automation in Power Generation

Automation has significantly improved power generation efficiency by streamlining operations in conventional and renewable energy plants. In thermal power plants, automated systems control turbine speed, fuel intake, and temperature regulation, ensuring optimal performance. In hydroelectric plants, automation enables remote monitoring of water levels and turbine functions, reducing manual intervention and improving safety.

Renewable energy sources, such as wind and solar farms, heavily rely on automation for effective operation. AI-powered predictive maintenance helps identify potential equipment failures before they occur, reducing downtime and maintenance costs. Additionally, automated weather forecasting models optimize energy production by adjusting panel angles in solar farms or altering turbine blade positions in wind farms.

Automation in Power Transmission and Distribution

The transmission and distribution of electricity involve intricate networks that require efficient management. Automation technologies such as Supervisory Control and Data Acquisition (SCADA) and Energy Management Systems (EMS) have transformed grid operations. SCADA systems allow real-time monitoring and control of substations, transformers, and circuit breakers, minimizing the risk of faults and ensuring quick restoration of services in case of failures.

Automated switching systems play a crucial role in managing load distribution. In case of faults or overload, these systems automatically reroute electricity to prevent disruptions. Moreover, automation enables self-healing grids that can identify and isolate problems without human intervention, thereby enhancing grid resilience.

Industrial Automation and Smart Factories

Industrial automation in the electrical sector has paved the way for smart factories that operate with minimal human intervention. Robotics, programmable logic controllers (PLCs), and AI-driven systems optimize manufacturing processes, reducing waste and improving efficiency. Automated assembly lines and quality control mechanisms ensure high precision in electrical component manufacturing.

Digital twins, a cutting-edge automation technology, are being used to create virtual models of electrical systems. These digital replicas help simulate performance, predict failures, and optimize design before implementing changes in the real world. The use of digital twins in power plants, substations, and electrical infrastructure enhances decision-making and reduces risks.

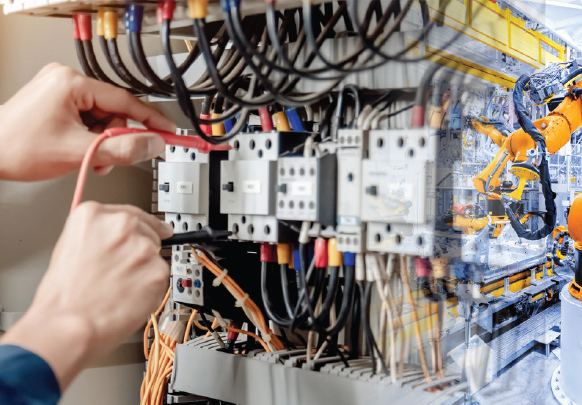

Automated Handling and Assembly in Switchgear Manufacturing

Automation has significantly improved efficiency in switchgear manufacturing by enabling automated handling, assembly, and conveying systems. Robotic arms and automated guided vehicles (AGVs) are used for precision placement of components, reducing manual errors and increasing production speed. Computer-controlled assembly lines ensure consistency and quality in manufacturing, while automated conveyors streamline material movement between workstations. Integration of vision-based inspection systems further enhances quality control by identifying defects in real-time.

These automated processes not only improve productivity but also enhance worker safety by reducing exposure to hazardous environments.

Impact on Safety and Workforce Efficiency

Automation has significantly improved safety standards in the electrical sector. Automated monitoring systems detect anomalies such as voltage fluctuations, overheating, and equipment malfunctions, preventing accidents. Remote-controlled and robotic maintenance systems reduce the need for human workers to operate in hazardous environments, minimizing the risk of electrical shocks, arc flashes, and exposure to high-voltage equipment.

While automation reduces the reliance on manual labor, it also demands a skilled workforce proficient in handling advanced technologies. The industry is witnessing a shift towards upskilling and reskilling programs, where workers are trained to operate and maintain automated systems. This transition ensures that human expertise is leveraged alongside automation for enhanced productivity.

The Role of AI and Machine Learning

AI and machine learning are playing a pivotal role in optimizing electrical automation. These technologies analyze vast amounts of data to identify patterns, predict failures, and suggest corrective measures. AI-driven algorithms help optimize energy consumption by dynamically adjusting supply based on demand fluctuations.

For instance, in energy trading markets, AI-powered predictive analytics enable electricity providers to make informed decisions on power generation and distribution, minimizing costs and maximizing efficiency. Additionally, ML-based algorithms enhance cybersecurity in the electrical grid by detecting and mitigating potential threats before they cause significant disruptions.

Challenges and Future Prospects

Despite the numerous benefits, automation in the electrical sector comes with its challenges. High initial investment costs, integration complexities, and cybersecurity threats are some of the hurdles faced by industry players. However, as technology evolves, automation solutions are becoming more cost-effective and accessible.

The future of automation in the electrical sector is promising, with emerging technologies such as blockchain, quantum computing, and edge computing expected to further enhance efficiency and security. Blockchain technology can streamline energy transactions and improve transparency in power trading. Quantum computing has the potential to optimize grid management by solving complex optimization problems in seconds. Edge computing enables real-time data processing at the source, reducing latency and improving system response times.

Conclusion

Automation is revolutionizing the electrical sector by enhancing efficiency, safety, and sustainability. From smart grids and AI-driven energy management to automated manufacturing and predictive maintenance, automation is driving unprecedented advancements. While challenges remain, continuous innovation and digital transformation will ensure that automation remains a cornerstone in shaping the future of the electrical industry. As the sector evolves, embracing automation will be key to building a resilient and intelligent electrical infrastructure that meets the demands of the modern world.

Automation in Power Generation

Automation in Power Generation