The article highlights the major application areas where the usage of nested wave springs is best suited

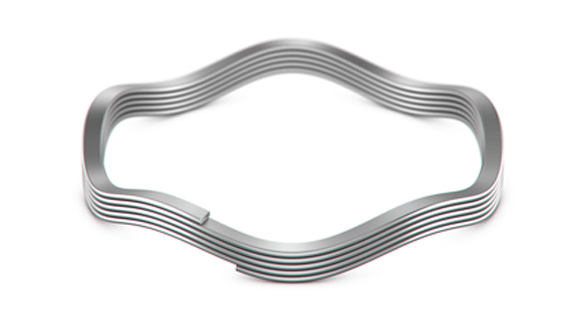

1. Nested springs have multiple turns, coiled in parallel to pro- duce higher forces. This type of wave spring is designed to produce very high spring forces compared to standard single-turn springs. Nested springs are used primarily in the automotive, oil & gas, and connector industries. They can be found in a variety of applications, such as seals and valves, and can be used to preload a bearing.Incorporate a Nested wave spring when your application requires more force. Nested wave spring forces in- crease proportionally with the num- ber of turns in the coil. Compressing a wave spring creates bending, or tensile stresses, which can limit the amount of force the spring can produce with- out failing or permanently deforming. It is recommended that that the calcu- lated operating stress be less than the minimum tensile strength of the mate- rial in static applications and less than 80% of the minimum tensile strength in dynamic applications. Stacking sin- gle- turn springs can achieve a higher load while distributing the stresses evenly across the parts. One Nested spring provides the desired load with- out the complication of stacking mul- tiple parts.

2 .Use a nested wave spring when mis- alignment during installation caused uneven loading. When the desired load requires multiple single-turn springs to be stacked in an assembly, consider a nested spring. The gaps in stacked single-turn springs must be aligned to prevent binding or uneven loading when compressed. Unlike stacks, nested springs are single, con- tinuous filaments of flat wire which guarantees the multiple layers stay aligned for consistent loading.

3 .Consider a nested wave spring when you want production to be simple and cost-effective. Unlike a stack of single-turn springs, which need to be individually installed to guarantee re- peatability, nested springs are a single part that can be dropped directly into the housing. This approach simpli- fies and speeds up installation, sav- ing time and money. Standard Nest- ed Spirawave® springs from Smalley offer a direct part cost savings when compared with stacks of comparable standard single-turn wave springs.

4 .Choose a nested wave spring when automatic handling is used during assembly. Other types of springs can be deformed by a robotic arm during a pick-and-place process or can tangle when placed in a hopper for vibrato- ry sorting and feeding. This results in lost time because the parts must be sorted and assembled by hand. Nested springs are ideal for automated pro- cesses because they have no floating ends and the turns sit tightly together, which prevents tangling. The multiple-turn configuration of the neste guarantees the multiple layers stay aligned for consistent loading.wave spring design is also sturdy, perfect for easy pick-and-place installation.

5. Use a nested wave spring when you need a heavy loading part, fast. If you need a quick sample of a carbon or stainless part in diameters from .500 to 4” or 16 to 100 mm, standard Nested Spirawave® Wave Springs from Smal- ley are available from stock for next day shipping. Additionally, there is only a three- week lead time for stand- ard parts in non-stock quantities. This means a sample can be procured very quickly to test in your application.

6. Customize a nested wave spring to meet your application requirements. Nested springs can be manufactured with nearly any number of turns to achieve the desired spring force. The material, size, and desired load are just some of the spring properties that can be customized. Every appli- cation has its own specific require- ments, and it is recommended to speak with an engineer before spec- ifying a custom component. Experi- enced spring engineers can provide the best solution when it comes to solving unique application challenges. Nested wave springs are an important part to consider when your application requires high spring forces or stacks of single-turn springs. Companies such as Smalley provide free samples of many of their products. Its years of ex- perience have shown that the simplest way to evaluate a product is to have it in-hand. Nested wave spring samples are available in a variety of configu- rations for you to try in your specific application.