Electric Motors Play An Indispensable Role In Modern Industry. However, In Hazardous Environments Where Flammable Gases, Vapors, Dust, Or Fibers Are Present, Conventional Motors Can Pose Serious Safety Risks Due To The Possibility Of Sparks, Arcs, Or Excessive Heat Igniting The Ambient Atmosphere. To Mitigate These Risks, Specially Designed Flameproof Motors, Also Known As Explosion-proof Motors, Are Used. These Motors Are Engineered To Operate Safely In Explosive Environments Without Igniting The Surrounding Medium, Making Them Essential In Sectors Such As Oil & Gas, Mining, Chemicals, And Pharmaceuticals.

This Article Delves Into The Key Design Aspects Of Flameproof Motors And Explores Their Real-world Applications Across Industries.

Understanding The Concept Of Flameproof Protection

Flameproof Motors Are Built In Such A Way That Any Explosion That May Occur Within The Motor’s Enclosure Is Contained And Does Not Propagate To The External Atmosphere. The Enclosure Must Withstand The Pressure Of The Internal Explosion And Prevent The Transmission Of Hot Gases Or Flames Outside.

The Motors Are Designed In Compliance With International Safety Standards Such As Iec 60079-1, Is/iec 60079, And Country-specific Norms Like Atex (Europe) Or Ul (Usa). In India, The Relevant Standard Is Is/iec 60079-1 For Flameproof Enclosures.

A Motor Is Considered “flameproof” Only If It Successfully Passes Stringent Tests For Pressure Containment, Flame Transmission, And Temperature Rise.

Key Design Considerations In Flameproof Motors

Designing A Flameproof Motor Is A Highly Specialized Task That Involves Careful Material Selection, Structural Reinforcement, And Precise Engineering. Below Are The Critical Design Considerations:

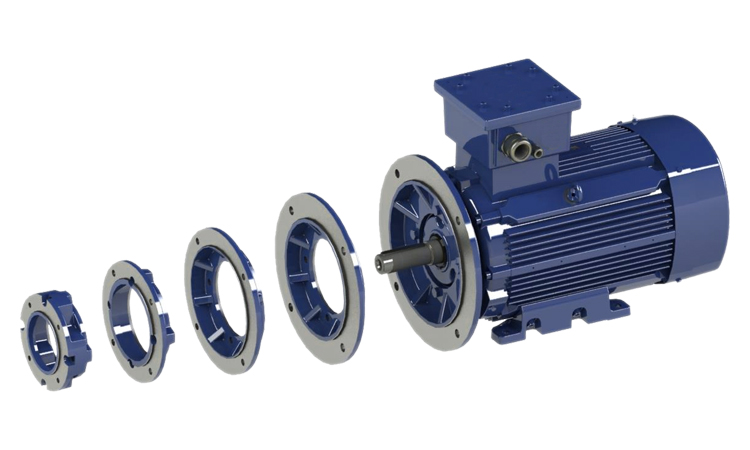

I. Flameproof Enclosure (Type ‘d’ Protection)

The Motor’s Enclosure Is The First And Most Important Line Of Defense. It Must:

Be Made Of Robust Materials Such As Cast Iron, Aluminum Alloy, Or Stainless Steel.

Withstand Internal Explosion Pressure (Up To 10–15 Bar Depending On The Hazardous Zone Classification).

Have Flame Paths (Also Known As Flame Gaps) – Narrow, Carefully Machined Gaps At Joints And Flanged Covers Which Cool The Escaping Gases And Prevent Ignition Outside.

Ensure Mechanical Integrity During Installation And Operation, Including Corrosion Resistance In Harsh Environments.

Ii. Temperature Class And Surface Temperature Control

One Of The Major Risks In Hazardous Areas Is The Surface Temperature Of Equipment Becoming Higher Than The Auto-ignition Temperature Of The Surrounding Gas Or Vapor. Thus:

Flameproof Motors Are Designed To Operate Within A Specific Temperature Class (T1 To T6).

T6 Means The Motor’s Maximum Surface Temperature Does Not Exceed 85°c, Which Is Essential For Environments With Low Auto-ignition Point Gases.

Proper Thermal Management Through Efficient Cooling Systems And Insulation Is Vital.

Iii. Flame Path Design

The Flame Path Is The Interface Through Which Internal Explosion Gases Exit The Enclosure. Key Aspects Of Flame Path Design Include:

Maintaining Minimum Path Length (Usually Several Millimeters).

Limiting Maximum Gap Width (E.g., 0.1 To 0.2 Mm).

Ensuring That The Surfaces Are Smooth, Corrosion-free, And Precisely Machined To Avoid Leakages.

Preventing Wear And Tear During Servicing That May Compromise The Gap Dimensions.

Iv. Cable Entry And Glands

Even A Minor Lapse In Cable Sealing Can Allow Flames To Escape. Therefore:

Certified Flameproof Cable Glands Must Be Used.

Glands Should Be Suitable For The Type Of Cable Used (Armored, Unarmored, Etc.).

The Cable Entries Are Often Threaded Or Flanged And Sealed With Compound Fillings.

V. Bearing Protection And Shaft Sealing

Bearings And Shafts Can Become Sources Of Heat Or Spark Due To Friction Or Electrical Currents. Hence:

Special Non-sparking Materials Are Used For Bearing Cages.

Seals And Labyrinths Are Provided At The Shaft To Prevent Ingress Of Gas Into The Motor And Escape Of Hot Gases.

Anti-friction Design Is Used To Limit Temperature Rise In Bearings.

Vi. Rotor And Stator Design

The Rotor And Stator Are Constructed With:

High-efficiency Windings To Reduce Internal Heat Generation.

Impregnation Materials That Are Flame-resistant And Stable Under High Temperatures.

Enhanced Slot Insulation Systems That Can Withstand Pressure And Temperature Surges In Case Of An Internal Fault.

Vii. Earthing And Grounding Provisions

Flameproof Motors Have Dedicated Earthing Terminals To Ensure That No Accidental Buildup Of Static Electricity Occurs On The Motor Body. Proper Grounding Is Mandatory To Prevent Accidental Sparking During Maintenance Or Operation.

Classification Of Hazardous Areas And Motor Selection

Flameproof Motors Are Deployed According To The Classification Of Hazardous Zones As Per Gas Group And Temperature Class. These Classifications Include:

Zone 0: Continuous Presence Of Explosive Atmosphere (Rare For Motor Installation)

Zone 1: Likely Presence Of Explosive Atmosphere During Normal Operation

Zone 2: Explosive Atmosphere Unlikely Or Only Present For Short Durations

Gas Groups Are Categorized As:

Group Iia, Iib, Iic, With Iic Being The Most Severe.

A Flameproof Motor Designed For Zone 1, Iic, T6 Classification Is Considered Highly Robust And Suitable For The Most Critical Applications.

Applications Of Flameproof Motors

Flameproof Motors Are Extensively Used In Industries Where Explosive Gases, Vapors, Or Dust May Be Present. Some Key Applications Include:

1. Oil And Gas Industry

From Upstream Drilling Platforms To Downstream Refining Plants, Flameproof Motors Are Critical In Powering Pumps, Compressors, And Mixers Where Hydrocarbon Vapors Are Present.

2. Chemical And Petrochemical Plants

Reactors, Distillation Columns, And Agitators Rely On Flameproof Motors For Safe Operation Amidst Volatile Chemical Vapors.

3. Mining Operations

Underground Coal And Metal Mining Environments Are Prone To Methane Gas Accumulation. Flameproof Motors Drive Conveyor Belts, Fans, And Crushers In Such Zones.

4. Pharmaceuticals And Paints

Manufacturing Of Medicines And Paints Involves Use Of Solvents And Volatile Organic Compounds, Necessitating Explosion-proof Motors In Mixing, Milling, And Ventilation Systems.

5. Grain And Food Processing

Fine Dust From Grains, Flour, Sugar, And Spices Can Create Explosive Atmospheres. Flameproof Motors Are Used In Storage Silos, Dryers, And Milling Machines.

6. Fertilizer And Pesticide Manufacturing

The Presence Of Ammonium Nitrate, Phosphates, And Toxic Gases Requires Flameproof Drives For Reactors And Packaging Systems.

7. Wastewater Treatment And Biogas Plants

Methane Generated During Sewage And Organic Waste Treatment Calls For The Use Of Flameproof Motors In Pumps And Blowers.

Maintenance And Safety Considerations

While Flameproof Motors Are Designed To Be Rugged And Safe, They Must Be:

Periodically Inspected For Integrity Of Flame Paths And Cable Glands.

Serviced Only By Trained Personnel Using Certified Tools And Techniques.

Operated Within Prescribed Voltage And Load Parameters To Avoid Overheating.

Any Unauthorized Modification, Damage To The Flame Path, Or Wrong Installation Can Nullify The Motor’s Certification And Compromise Safety.

Conclusion

Flameproof Motors Are A Cornerstone Of Safe Industrial Operation In Hazardous Environments. Their Design Is Governed By A Combination Of Mechanical Strength, Thermal Control, Precision Engineering, And Regulatory Compliance. From Oil Rigs To Grain Mills, These Motors Ensure Continuity Of Operations While Preventing Catastrophic Incidents Due To Fire Or Explosion. As Industries Evolve Towards More Stringent Safety Standards And Automation, The Role Of Flameproof Motors Will Continue To Grow, Underscoring The Importance Of Sound Design, Correct Application, And Meticulous Maintenance.