Gearboxes are fundamental mechanical components used to transmit power and control speed and torque in various industrial applications. They are found in nearly every type of machine, ranging from simple household devices to the most advanced engineering systems, such as automotive and aerospace applications. In arduous applications— environments that involve extreme conditions such as high load, temperature fluctuations, vibration, contamination, or corrosive substances—gearbox design becomes especially critical. This article explores the design considerations and solutions for gearboxes that are deployed in challenging environments.

Understanding Arduous Applications

Before diving into the specifics of gearbox design for arduous applications, it’s important to define what these environments entail. An “arduous application” refers to any industrial operation or environment where the operational conditions are more extreme than those encountered in regular machinery applications. This could include:

- High Load and Torque: Applications requiring the transmission of significant amounts of power.

- Temperature Extremes: Gearboxes used in environments with very high or low temperatures.

- Corrosive or Harsh Chemicals: Applications involving exposure to chemicals or substances that could cause degradation.

- Vibration and Shock Loads: Industries where heavy, sudden forces or high levels of vibration are common.

- Contaminated Environments: Operations exposed to dust, water, dirt, or other particles.

Examples of such applications include wind turbines, heavy mining equipment, marine propulsion systems, and high-speed trains, among others.

Key Design Considerations for Gearboxes in Arduous Applications

Designing a gearbox for arduous applications requires addressing several key factors to ensure durability, reliability, and optimal performance.

1. Material Selection

The choice of materials for gears, shafts, casings, and bearings is crucial when designing gearboxes for demanding environments. In environments with high temperatures, corrosive materials, or extreme load, materials must withstand wear and tear over time. Common materials used include:

- High-Strength Alloys: Steels with high tensile strength and fatigue resistance are often used in gears subjected to high load and torque.

- Stainless Steel: For applications exposed to corrosive chemicals or seawater, stainless steel is preferred due to its resistance to rust and corrosion.

- Hardened Steels and Coatings: Surface treatments such as carburizing or nitriding increase hardness and resistance to wear and fatigue.

- Non-Metallic Materials: In some cases, non-metallic materials, such as reinforced composites, are considered for lightweight or non-corrosive applications.

Selecting the right material ensures that the gearbox can endure the rigors of the environment, including wear from friction, thermal expansion, & exposure to chemicals.

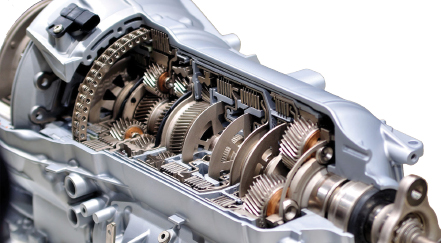

2. Heat Management and Lubrication

Heat is a significant issue in arduous applications, particularly those that involve high-speed or heavy-duty operations. Excessive heat can cause premature wear, reduce efficiency, and even lead to failure. Effective heat dissipation and lubrication are essential in maintaining gearbox performance.

- Cooling Systems: Gearboxes designed for arduous applications often incorporate additional cooling mechanisms such as external fans, oil coolers, or even liquid cooling systems.

- Lubrication Types: The selection of lubricant is critical. Synthetic lubricants, for example, are often used in high-temperature environments due to their stability under heat. In environments prone to contamination, oil filters and sealing systems help to maintain the quality of the lubricant.

- Sealing Solutions: In contaminated environments, it’s essential to prevent dirt, dust, and moisture from entering the gearbox. Special seals and gaskets are employed to protect the internal components and maintain lubrication integrity.

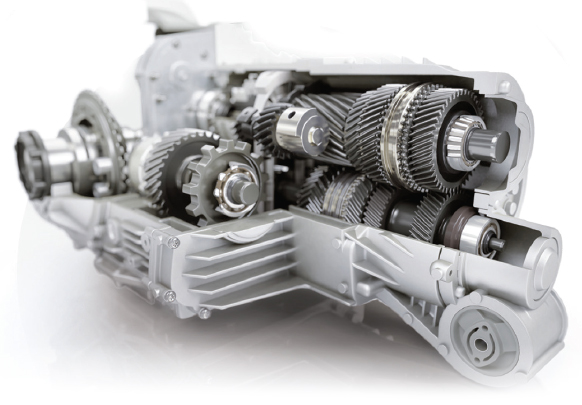

3. Gear Geometry and Tooth Design

3. Gear Geometry and Tooth Design

The geometry of the gears, including tooth shape and size, plays a pivotal role in ensuring efficient power transmission. In arduous applications, gears are subjected to heavy loads, shock, and stress. To prevent failures such as tooth wear or fracture, the tooth design must be optimized for high load capacity.

- Tooth Geometry: The involute tooth profile is commonly used because it ensures smooth meshing and minimizes the potential for sudden impact loads.

- Tooth Surface Treatments: Tooth surfaces may be hardened or coated to enhance wear resistance. Techniques such as shot peening, flame hardening, and nitriding are used to increase fatigue resistance.

- Gear Type: Helical gears are often preferred for high-load, high-torque applications due to their smooth engagement and load distribution. Spur gears, while more straightforward to manufacture, are typically used in simpler, lower-load scenarios.

4. Load Capacity and Strength

In arduous applications, gearboxes are often exposed to sudden load changes or high torque that can place significant stress on the components. Properly accounting for these stresses in the design is essential to prevent failure.

- Fatigue Analysis: Gearbox designers employ fatigue analysis to ensure that gears and shafts can endure cyclic loading over long periods. This includes evaluating the contact stresses and ensuring that they fall within allowable limits.

- Tooth Strength and Durability: The gear design must balance the need for strength (to withstand high loads) and durability (to avoid excessive wear). Overengineering components for strength can lead to unnecessary weight and inefficiency, while underestimating the strength requirements can lead to failure.

5. Vibration and Noise Control

In environments where vibration is significant—such as in wind turbines, railways, or mining equipment—gearbox design must mitigate the effects of vibration. Prolonged vibration can lead to gear misalignment, bearing failure, and premature wear.

- Dynamic Load Analysis: Designers employ advanced simulation techniques to assess the dynamic loads and the natural frequencies of the gearbox components to avoid resonance and excessive vibration.

- Damping Mechanisms: Damping solutions such as shock absorbers or vibration isolation mounts can be used to reduce the impact of external vibrations on the gearbox.

- Noise Reduction: In many applications, noise reduction is critical. Techniques such as optimizing gear mesh, improving tooth profiles, and using sound-absorbing materials help in reducing noise levels.

6. Compact Design and Weight Optimization

Space constraints are common in many arduous applications, particularly in automotive and aerospace sectors. Additionally, weight reduction is often a priority, especially in mobile or airborne machinery.

- Gearbox Layout: A compact design is required to minimize the size of the gearbox while maintaining strength. A well-thought-out layout ensures that the gear train is aligned to optimize space without compromising strength.

- Lightweight Materials: In applications like aerospace or marine, lightweight alloys or composite materials are often used to reduce weight while maintaining performance. However, the use of lightweight materials must not come at the cost of strength and durability.

7. Maintenance and Accessibility

Arduous applications often involve remote locations, harsh working conditions, and limited access to the machinery. Therefore, gearboxes in such environments must be designed for ease of maintenance and repair.

- Modular Design: Gearboxes that allow for easy disassembly and reassembly with minimal downtime are essential. Modular components also reduce maintenance complexity.

- Monitoring Systems: In critical applications, real-time condition monitoring systems can provide insights into the health of the gearbox, detecting issues such as overheating, misalignment, or excessive vibration before they lead to failure.

- Lubrication and Seal Design: As noted earlier, effective sealing and lubrication are crucial. Using accessible grease ports or advanced filtration systems can extend the life of the gearbox and reduce the frequency of maintenance.

Conclusion

The design of gearboxes for arduous applications is a complex engineering task that requires a deep understanding of material science, thermodynamics, mechanics, and environmental conditions. In industries where machinery is exposed to high loads, extreme temperatures, corrosive substances, or vibration, designing a robust and efficient gearbox is essential for ensuring continuous operation, minimizing downtime, and avoiding costly repairs. By carefully considering factors such as material selection, heat management, lubrication, and vibration control, engineers can create gearboxes that stand the test of time, even in the most demanding environments.