ESPRIT is the formula for success for Metri-Tech

In its 30,000-square-foot facility, Metri-Tech manufactures ultra-precision, high-volume critical components for the aerospace, medical, defense and commercial industries

Metri-Tech Engineering, Inc., in Huntington Beach, CA, isn’t your typical job shop that much is evident from the company’s shop filled with automated production equipment, including a wall-mounted Live Scheduler, which resembles a six-foot tall iPad. Hans Gratzer, Jr., COO / CTO of Metri-Tech and son of company founders Hans Sr. and Katharina Gratzer, developed the scheduling program to help his 38 employees better visualize what is going on in the shop at any given time and plan for their next jobs. It’s part of the company’s forward-thinking approach to automation.

“Most job scheduling systems are number-driven. But people like pictures,” Gratzer says. “With this system, what you see is what you get kind of like ESPRIT.”

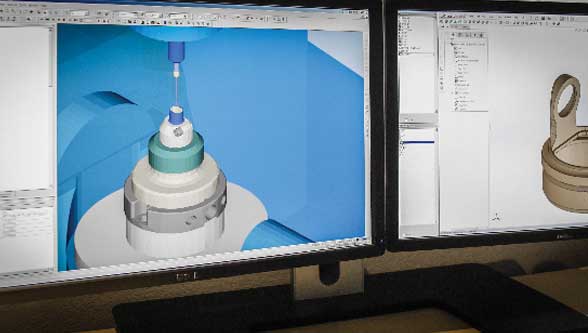

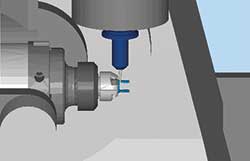

Metri-Tech has used ESPRIT almost since the CAM software’s inception Gratzer estimates they first installed it in 1988. “My dad bought the software, and he was very happy with it because we were mainly in the fitting business at that time; he liked that it could program families of parts very well because they’re similar geometries, they can be adjusted very easily with ESPRIT. It was a huge time savings.” But just as crucial to Metri-Tech were ESPRIT’s accurate, full-color simulations the first in the industry. “That allowed us to give more visibility to our programming and reduce mistakes in our setup the first time around. Most of our machinists do both the setup and the machine operation, they know what they’re doing. Now they do not have to worry during the setup process and first piece run; they know the program will be right due to the precise nature of ESPRIT simulation, setup sheets and posts.” Thirty years later, ESPRIT keeps Metri-Tech at the top of its game, thanks to its ease of use and quick support. The company uses the software for full 5-axis, contour composite milling, swarf milling and multi-axis multi-spindle turning. “ESPRIT is very progressive in the 5-axis and multi-axis realms,” Gratzer notes. “ESPRIT is just easier, faster, stronger and more accurate than other CAM programs we have tested or demoed over the years.”

In its 30,000-square-foot facility, Metri-Tech manufactures ultra-precision, high-volume critical components for the aerospace, medical, defense and commercial industries in all types of materials, including more exotic materials like Inconel, Titanium, Nitronic, Invar, Kovar, Ferrium, Polyurethane, Teflon, PEEK and Ultem to name a few. “Customers use us as a solution: they have problems and we fix them,” Gratzer says. “We’re experts in most manufacturing processes, and our customers come to us for the precision and quality of the parts we produce.” The company started out making fittings, which provided them an understanding of how they fit into the larger assemblies. This allowed them to gradually move into more complicated parts. “Doing fittings evolved into us going in the opposite direction: manufacturing the parts the fittings fit into, which were housings and manifolds. Then obviously when you get into the more complex and assembly side of medical and aerospace, you get into the critical finishes and close tolerances of the internal workings of the manifolds and housings like spool and sleeve assemblies and shaft work. It was a very interesting and methodical transition.”

The company operates 42 machines in total with a number of 3-axis Mori Seiki lathes and Nakamura-Tome lathes with up to 13 axes, which allow the company to be more creative with small parts. Metri-Tech also runs 3 and 4-axis vertical mills and several Matsuura full 5-axis vertical trunnion machines with up to 42 pallets and 520 tools. Combined, Metri-Tech’s arsenal of machines provide programmers with hundreds of pallets and thousands of different tool options. Many of the shop’s palletized machines are robotic, and the company is working to bring in mobile robots to transfer parts from machine to machine and virtual augmentation to help programmers easily view their custom manufacturing software and scheduler on the shop floor.

Metri-Tech, which boasts an ISO AS9100D certification, offers polishing and ultra-critical finishes, as well as a high-end quality control facility in-house. “What sets Metri-Tech apart from the competition is quality on larger volumes. Anybody can make a few good parts, but consistency and repeatability over larger volumes is the key to our success. Most customers say that quality is a given nowadays; it’s truly not,” Gratzer says. “We take so many steps in assuring a quality part gets to the customer. We have a group of very dedicated employees, and everybody’s looking out for the quality of the product. The main reason why customers come to us is 100% quality, all the time. If they need a job done fast and they need it done right the first time, they come to us.” Metri-Tech’s performance has been strong since its inception in 1978, but shortly after Gratzer came to work for the company in 1998, and with his vision for technology, automation and reinvestment, they have experienced significant growth. Forecasts show it may double its business within short order and “I give credit to our passion for this industry, striving for automation and all the products we use, including ESPRIT,” Gratzer says. “I feel our next 40 years are going to be stronger than the last 40.”

For more information

Web:www.espritcam.com