Founded in St. Petersburg in 2001 as a tool distributor, Green Tools is now a leading manufacturer of cutting tools, providing circular saws and other woodcutting machines for the sawmill, furniture, and woodworking industries throughout Russia.

Choosing a machining center

As the company’s tool-making business grew, the complexity of its production jobs also increased; in time Green Tools found that the complicated geometry of the parts it was making was beginning to exceed its production capabilities. Without an in-house CAM system, the company was forced to sub-contract some of its more challenging jobs to other shops, a situation that not only proved to be expensive and slow but often resulted in lower quality parts. After evaluating its expanding manufacturing challenges, Green Tools made the decision to purchase its own equipment with a view to doing all of its 5-axis machining in-house. It went in for a HAAS UMC-750SS CNC vertical milling center.

Finding the right CAM system

After acquiring the HAAS, Green Tools then needed a CAM system that would seamlessly integrate with the milling center, enabling them to ramp up production and make full use of their new 5-axis machining capabilities. The company then decided to run some test operations using ESPRIT, DP Technology’s powerful CAM system, and were pleasantly surprised at the results. “The program is different from all the others that we tried. Powerful product functionality combined with a reasonable price, a user-friendly interface, the availability of certified postprocessors, and the software’s ability to create a virtual model of our machine – these were among the main factors that influenced our decision to purchase ESPRIT,” says Kirill Smolin, technical consultant at Green Tools.

Green Tools was also pleased with the high level of customer service they received from the software reseller, LOCNITI. Prior to the arrival of the HAAS equipment, LOCNITI had multiple consultations with Green Tools and conducted training sessions with ESPRIT a couple of weeks before the vertical milling center was delivered. “By the time we received the machine, we were not only aware of ESPRIT’s potential, we already knew how to work using the software, which, of course, is a big plus,” comments Smolin.

Implementation of the ESPRIT CAM system

Having been trained in the ESPRIT CAM system, Green Tools specialists immediately began work on creating control programs to use on the HAAS equipment. “Programming 5-axis machines is quite a difficult task, so we were very pleased with the availability of good technical support,” says Smolin. Throughout the CAM implementation process, the engineers of LOCNITI provided skilled assistance in mastering the ESPRIT system, including ‘live’ technical support onsite at Green Tools, and quickly resolved all issues that arose.

It didn’t take long before Green Tools knew that it had made the correct decision in bringing its machining operations in-house. “Buying our own equipment and implementing the ESPRIT CAM system was the right solution. We no longer need to contract services from third-party organizations, and it also became easier to exercise control and make changes to the production process,” says Smolin.

Using ESPRIT to create a cabinet milling cutter

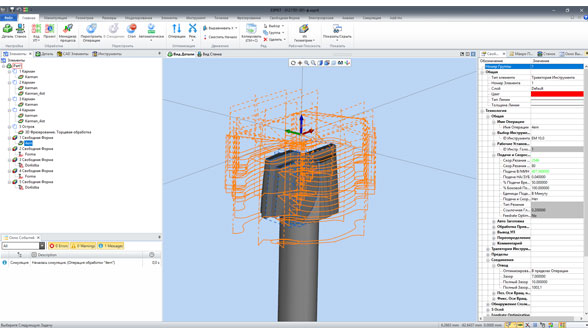

The process of making a cabinet milling cutter illustrates how adopting a powerful and flexible CAM system has helped advance Green Tools’ manufacturing at ESPRIT. After first writing the initial CNC program for the part, Green Tools engineers run a simulation of the programming in ESPRIT before actually milling the part on the machine. The software provides full machine tool simulation in real time, enabling programmers to see a virtual version of the complete machining operation before it begins – including all elements of the process such as the machine, workpiece, spindles, and turrets. This ensures the accuracy of the toolpath generation and facilitates easy optimization of machining parameters. It also saves time – being able to see and review the programming before the part goes into the machine is significantly more productive than the previous method of programming the job at the machine, a task that took up valuable time that could have been used to manufacture parts. Additionally, the software’s Collision Detection feature finds and alerts programmers to collisions between the tool assembly and the stock, ensuring that collision-free toolpaths are created. “The high quality and accuracy of ESPRIT’s virtual machine environment visualization allowed us to avoid errors and program correction on the machine,” explains Smolin. Once the programming is complete, the final step is machining the product on the HAAS milling center.

“We have a wide range of products, and this requires quick and accurate preparation of control programs and processing of the parts. With ESPRIT as our CAM system, I am confident that Green Tools can meet all future manufacturing challenges,” states Smolin.

For more information about ESPRIT, contact: www.dptechnology.com