Small Parts Inc. makes, well, small parts – to the tune of as many as 370 million a year, with sizes ranging from as small as 0.190 inch square to 0.004 inches thick. Using the automating power of ESPRIT, the company speeds up the stamping of all of these little parts, while easing the often-intricate programming process.

Small Parts Inc., based in Logansport, Indiana, USA, with locations in Juarez and Reynosa, Mexico, manufactures metal stampings and assemblies and has special expertise in non-ferrous applications and ferrous applications requiring spring qualities. In addition to manufacturing general stampings, Small Parts works primarily in transmission and safety restraints, and low voltage distribution and meters. Founded in 1958, the company now employs nearly 350 people across its three locations. The company produces about 370 million parts a year, with sizes ranging from as small as 0.190 inch square to 0.004 inches thick. The company’s jobs are in production volume sranging from 50,000 to more than 30 million stampings.

Small Parts designs and manufactures its own stamping dies in order to keep the process in house and minimize the time it takes. In addition to stampings, Small Parts has welding, tapping, riveting, staking, deburring and tumbling capabilities. Small Parts also owns a state-of-the-art cleaning system for parts with stringent cleanliness specifications.

Small Parts chose ESPRIT in 1996 because it was the most compatible software with its patchwork of machines — at the time, Small Parts ran Charmilles machines with CMD and Fanuc controls, a Fanuc wire EDM and an AgieVision wire EDM. In 2001, the company purchased the ESPRIT milling package.

“We were provided with excellent training and service, and it made a huge difference for us,” says the CNC lead manager at Small Parts, Bill Butner. “Small Parts depends on ESPRIT, and they’ve been dedicated to helping us succeed.”

Since 2012, Small Parts has gradually replaced most of its wire EDM machines with Sodicks, chosen because of their competitive pricing and excellent customer service. The company currently runs SL600Q, SLN600G, ALN600G wire EDM machines and a recently purchased ALN400G, while also continuing to run a Charmilles 440. The EDM department also uses a Sodick AG60L vertical (RAM) EDM, for producing special forming tools and doing orbit tapping, and a Chmer CNC EDM drilling model AH64C with tool changer. Small Parts’ milling operation uses a Matsuura VX-1000, Hyundai-Wia F400 and a Haas VF-3.

The company’s jobs have involved nearly every kind of metal but most production is in brass or copper. Roughly half of these parts go to customers in the automotive industry, with the remaining half going to medical customers and appliance manufacturers. While all of these parts are small (hence the company’s name), some of them are so complex that other companies won’t even quote for them.

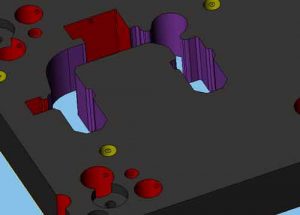

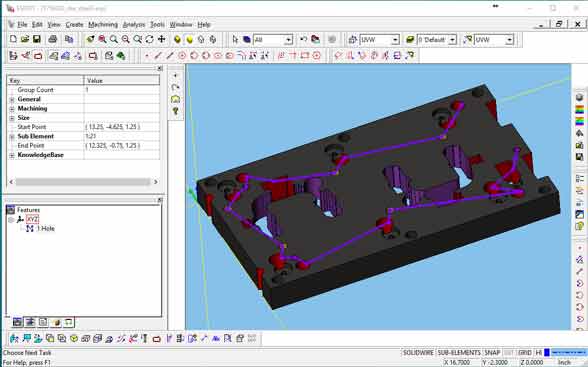

One such part was the tool Small Parts created in order to stamp an electrical shield for an automotive manufacturer; Small Parts produces half a million of these stampings each year. The stamping tool was wire cut using dowel settings, identically sized punches and retainers that needed to be slip fit, oversize purchase punches, land and taper settings, and open cut setups in ESPRIT. Made from tool steels, the tool required tight punch & die clearance and very small holes. There were nearly 200 different details required to build it. Several details were very large, and with over 200 inches of feed, the advanced sorting operation feature was required: this created one pit stop to remove the slugs. Because the job was unattended, holding the slug in place while the workpiece was being wire cut required a special strategy:as the shape was almost completed, a small separation prevented the part from falling into the work tank. The EDM machine roughed the entire detail, then cut the separation to remove the slugs. Because of tight clearances, three skims were needed. All of this was completed within 24 hours of unattended operation.

To program all the details to build the tool, Butner used ESPRIT in 3D solid mode. Then, to cut the internal holes and the outside perimeter burns of the progressive die, Butner used the legacy hole recognition feature to program his EDM hole driller, as precise location was a must. After using the feature to connect all holes with one PTOP and define the thread points, Butner utilized the color coding and the grouping properties features to find the profile cavities to be wire EDM cut in just one click. All Small Parts programmers use the wire EDM expert system and save their settings, which can be customized later and assure accuracy when loading the wire EDM technology. “The EDM expert system XML files can be applied to each cut by inputting wire diameter, material, finish and accuracy. This will generate the correct parameter settings and offsets,” Butner says.

“Making a bunch of stampings is a really long process, but with ESPRIT it’s so easy, especially with the ability to automate and save settings for later,” Butner continues. “We’re really excited to see what the future of ESPRIT holds for us.”

For more information about ESPRIT, contact: