OMRON introduces new functions for its Robotics Integrated Controller

Virtual teaching function to reduce 90%*¹ production equipment commissioning time for inspection processes

Complex visual inspections that rely on skillful operators to support rapid increased production also automated

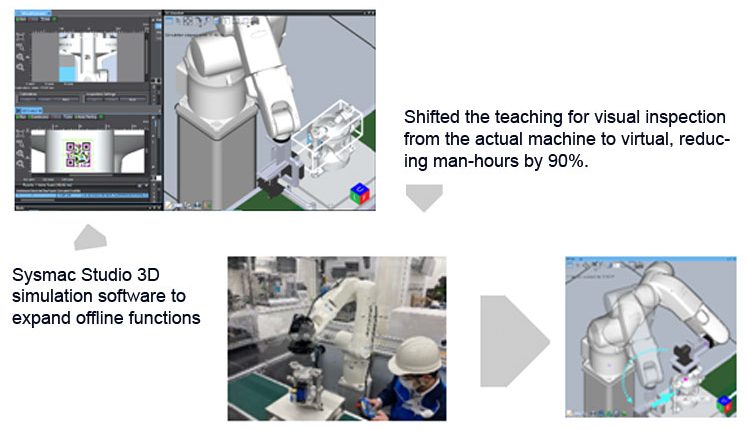

OMRON Corporation (Shimogyo-ku, Kyoto, Japan; President & CEO: Yoshihito Yamada) announced the expansion of its “Sysmac Studio 3D Simulation” with the inclusion of the offline teaching functions. This is a simulation software for “Robotics Integrated Controller” which integrates and controls robots and control devices like vision, servo and safety that make up production equipment.

In addition to a shortage of skilled engineers, manufacturing sites face the challenge of increasing the number and complexity of inspection items prior to shipment, which requires a lot of time. However, while automation at manufacturing sites is advancing, the automation of the inspection for complex products has been slow to progress because it often relies on the experience and visual inspection of skilled technicians. In addition, the equipment development system that relies on skilled engineers requires improvement because of the man-hours required to adjust the actual equipment.

The new expanded functionality in the Sysmac Studio 3D Simulation enables virtual teaching of the motion of a camera-mounted arm robot for product inspection. For example, the teaching of an automotive part with 20 to 30 inspection points can be completed in about one hour on a desk using the new function, whereas the conventional preparation work with the actual product or actual machine would have needed one day. In addition, virtual teaching enables remote pre-preparation on a laptop, even if the operator is forced to work remotely due to the Covid-19, so that on-site work is limited to fine-tuning, thereby reducing the workload of workers at manufacturing sites that are suffering from labor shortages. With CAD data, the inspection target can be virtually converted to 3D and taught while the product is still in the design phase. It also shortens the time required to start up production of new products.

OMRON strives to promote DX of diversified and complex manufacturing sites through the “Robotics Integrated Controller” and “Sysmac Studio 3D simulation” to address customers’ challenge.

Features of this additional functionality

Three new functions using 3D simulation to shorten on-site work:

- The virtual shooting function allows the user to check the shooting status offline to determine if the camera position and angle of view are correct.

- The robot hand position and camera focus position can be precisely specified by the snap function (position teaching) to the object. The coordinates of the camera, robot, and inspection workpiece are automatically calculated to can teach the robot’s moving position.

- The Robot Path Planning function automatically generates paths to avoid obstacles while the robot hand or workpiece is being held, making robot teaching work faster and easier.

Features of the Robotics Integrated Controller

The industry’s first “Robotics Integrated Controller” seamlessly integrates the control of robots and control devices with peripheral equipment. The “integration of control,” which highly automates complex tasks that could only be performed by humans, and the “integration of the construction process,” which streamlines everything from system construction to maintenance through accurate real and virtual simulation technology, provide innovative applications that incorporate robots. With a strong focus on developing and improving products and services to meet the needs of our customers, OMRON, with the wealth of application knowledge and technology it has cultivated over the years, will realize applications for inspection and alignment that do not stop moving and also highly automated applications for craftsmanship with its “various control equipment groups” necessary for manufacturing.

Features of Sysmac Studio 3D Simulation

Simulation software that can reproduce the entire facility digitally and easily verify its operation with the same accuracy as the actual equipment by utilizing the Robotics Integrated Controller. The software can also simulate entire facilities, including custom robots developed in-house by the customer and equipment from partner companies. In addition to OMRON’s extensive lineup of control devices, including robots, the software can verify a wide range of entire facilities, including customers’ custom robots and equipment from partner companies, thereby helping manufacturing industry improve their production capacity and achieve everything from facility startup to maintenance in a short period of time.

*¹90% reduction: In cases where the number of inspection items is as large as 20 or more and preparation work on the actual equipment takes a long time (e.g., about 1 day), the man-hours saved by setting up inspections in a virtual space are calculated (March 2022: based on our own research). Internal evaluation results as of March 2022.

About innovative-Automation

OMRON advocates the value creation concept “innovative-Automation” that creates social value by

solving problems at the manufacturing site. OMRON aims for sustainability that realizes coexistence with the global environment and people’s well-being while driving manufacturing innovation by advanced automation. “innovative-Automation” invites people to a more creative role, embodying three concepts: “Autonomation beyond human abilities” that maximizes onsite productivity and energy efficiency, “Advanced collaboration between people and machines” that maximizes the potential of people, where machines and people evolve together, and “Digital Engineering Transformation” that reproduces manufacturing sites and equipment in a digital space, accelerates DX at manufacturing sites, and contributes to business process innovation.

About Omron Corporation & OMRON Automation in India

OMRON Corporation is a leading automation company with its core competencies in Sensing & Control + Think technology,and is engaged in a wide range of businesses including control equipment, electronic components, social systems, healthcare, and the environment. The company employs approximately 30,000 people worldwide and provides products and services in about 120 countries and regions. For more information, please visit https://www.omron.co.jp/

OMRON Automation – India, now more than two decades old in the country, caters to varied industrial applications encompassing the wide requirements of packaging, automotive, material handling, food & beverages, digital and panel building applications. The company is focusing on the solution business, including Robotics and IIoT, providing “One Stop” solutions to improve the overall efficiency on diverse production sites. Focusing on the themes of quality, safety and the environment, it supports manufacturing innovation with its unique sensing & controlling technologies and caters to customers across the country via its strong network of offices, application, service and sales engineers supported by an automation technology centre (for demos and PoCs), training centres as well as channel partners to address the ever- challenging requirements. A major factor in OMRON’s progress globally & locally has been the strong commitment to provide solutions towards its customers’ unique challenges.

To learn more, please visit: www.omron-ap.co.in