DOLD Safety system with personal keys

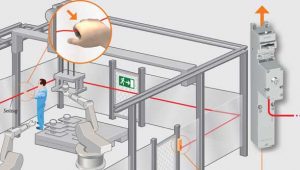

No matter if for maintenance measures or to eliminate minor malfunctions, hazardous areas around machines and in plants need to be entered again and again. It is important to ensure that people are not being harmed. Furthermore, it is essential to be able to leave the areas protected by safety fences unharmed at any time. If this is not ensured, accidental lock-ins may have tragic consequences. This is why reliable measures against lock-ins are essential for cases like these. In addition, an unexpected restart of machines must be prevented as long as there are people in the hazardous area. Depending the risk-assessment There are different approaches to prevent these risks.

Escape Release Opens Safety Gate

If safety gates to prevent access to passable hazardous areas are equipped with electromechanical guard locks (interlocks) escape releases are often used as lock-in protection. In order to ensure the sensible usage of an escape release in an emergency, the person trapped in must be able to reach and open the escape door in good time. If this is not the case, e.g. in extended or confusing hazardous areas, a standard escape release on the door is not suitable. For these applications an escape release via cable pull that is able to open the door from a greater distance or a personal key is recommended instead.

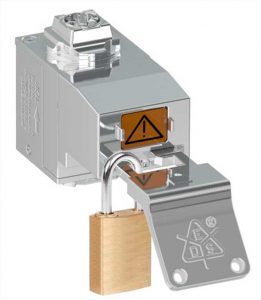

Personal Key as Lock-In Protection

Acc. to ISO/TS 19837 an escape release is usually not required if a personal key (key-in-pocket) is available. It serves to protect its carrier and must be removed from the guard lock of the safety gate before the hazardous area is entered. This serves to keep the machine stopped and unlock the door. Only after the coded key is reinserted into the guard lock is it possible to lock the door and start the machine again. As long as the machine operator carries the personal key, he or she is allowed to enter the hazardous area. This reliably prevents the lock-in of the person carrying the key and an unexpected machine start.

Choice of Safety Measure

Different criteria need to be considered to determine if a “personal coded key” or an “escape release” is the better lock-in protection for a particular application. The personal coded key is often the safer option. As mentioned before, the escape release only offers sufficient lock-in protection if the escape door can be reached at any time during a lock-in. If a standard guard lock is equipped with an escape release the safety gate can be closed, locked, and the machine can be restarted by unauthorised persons. In case people are in the hazardous area when this happens this may have severe consequences. To prevent this, additional protection measures are required. The problem is usually solved by LOTO measures (lock out tag out), which are depending upon the free will of the operator.

In some applications, however, escape releases cannot be realized for technical reasons because the escape release controls cannot be mounted at the danger side. These include containers, mixers, press chambers or cramped engine rooms. The personal coded key is the ideal solution as a preventive safety measure against lock-in and the restart of a machine.

Strengthening of the Machine Directive

A comparison of the current machine directive 2006/42/EG with the previous 98/37/EWG reveals an essential difference. Whereas the old directive stated the “risk of remaining locked in a machine” the current version addresses the “risk of getting locked in a machine” in appendix I, para. 1.5.14. This means: while the old directive considers an escape or emergency unlocking as sufficient, the current version requires preventive protective measures.

Personal Key for Better Safety

The safety switch and key transfer system SAFEMASTER STS by Dold & Söhne meets all requirements of the current machine directive. The personal key is an integral element of the TÜV (Technical Inspection Authority) certified safety system. As opposed to LOTO the lock-in protection is not only optional but enforced in this system: Only after the personal coded key is removed can the safety gate be opened to access the hazardous area. The system also includes units into which several keys can be integrated so that several people have their own keys at their disposal. SAFEMASTER STS combines the advantages of safety switches, guard locks, key transfers and command functions in one system. Its modular design and the extendability allow for flexible adaptation to the respective application. The STS-units are available in stainless steel and plastics and can be used in any combination. The safety switch and key transfer system is suitable for use in safety applications up to category 4 / PL e acc. EN/ISO 13849-1. Non-wired protection of safety gates is also possible. This reduces the installation, retrofitting and maintenance efforts. Apart from maximum safety, SAFEMASTER STS thus also offers significant savings potentials.

Conclusion:

There are different ways to provide for safe escape options from hazardous areas. However, safety concepts based on preventive protective measures are preferable. In other words, the lock-in of people in the hazardous area is prevented beforehand. Furthermore, a machine start is reliably prevented as long as there are people inside. Thus, a safety system with personal keys can be considered the ideal solution in many cases.

Authors: Arthur Aartsen, Business Development Manager with E. Dold & Söhne KG in Furtwangen, member of several standardisation bodies, among others DIN NA 095-01-04 GA and ISO TC 199/WG7

For more information

DOLD Electric India Pvt Ltd

E-mail: m.diwanji@dold.in

Website: www.dold.in