Continuous Emission Monitoring Systems (CEMS) play a vital role in tracking and reporting emissions from industrial processes. These systems provide essential data for regulatory compliance, environmental protection, and public health. However, their accuracy and reliability are paramount.

Let’s explore why testing CEMS is necessary and how it ensures the quality of performance and quality of emissions data.

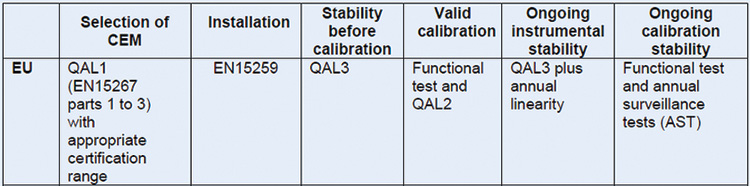

EN 14181 is a standards related to Quality Assurance Levels for CEMS specifies the procedures and requirements for the initial and periodic testing of CEMS to ensure that they meet the necessary quality standards.

The testing procedures outlined in QAL-1 include initial acceptance testing, which is conducted when a new CEMS is installed or when major modifications are made to an existing system. This is followed by periodic testing, which is typically conducted on Regular Basis ( QAL-3)/annually (AST)/ every Five (QAL-2) years, as per requirement of EN 14181.

The significance of testing CEMS according to QAL-1 standards is multifaceted:

- Compliance : Industries are mandated to monitor and control emissions, necessitating accurate and reliable CEMS data for regulatory compliance.

- Performance: CEMS complexity exposes them to various environmental factors, making testing imperative to ensure they operate within design specifications and provide dependable results.

- Quality Assurance: Testing guarantees CEMS deliver precise and consistent data, crucial for informed decision-making and regulatory adherence.

- Environmental Protection: Accurate emission measurement aids in mitigating the adverse effects of pollutants on the environment and public health.

- Cost Savings: Timely testing prevents costly damages or downtime, reducing expenses associated with equipment malfunction or non-compliance penalties.

Post-testing of CEMS, including Quality Assurance Level 2 (QAL2), Annual Surveillance Test (AST), and Quality Assurance Level 3 (QAL3), holds paramount importance due to several reasons:

- Continuous Performance Assurance: Detailed assessments ensure long-term stability and precision, ensuring consistent emission data reliability.

- Regulatory Compliance: Mandated tests uphold regulatory requirements, averting penalties associated with non-compliance.

- Data Integrity: Post-testing safeguards data accuracy, essential for regulatory reporting and environmental assessments.

- Environmental Protection: Accurate data aids in assessing and mitigating industrial activities’ environmental impact.

- Operational Efficiency: Prompt identification and resolution of issues optimize CEMS performance, minimizing downtime.

As per the CPCB Guideline 2014 / Guidelines 2018 , Red category industries has to installed CEMS as per European standards. So far this facility was available in Germany and UK, hence in India all industries were installing Overseas manufacturer equipment and further they were not in position or it was unpractical to send the equipment to Germany and UK laboratory for retesting of system as per European standards .

To address this challenge, we initiated to develop, testing laboratory equivalent to TUV Germany & NPL UK to test AMS/CEMS as per EN 14181, EN 15267-3, EN 15259, QAL-1 , QAL-2, AST to Reduce Import dependency.

TCQA LABS is a Testing & Calibration Laboratory accredited as per ISO IEC 17025:2017 by an International Accreditation Service, U.S.A,for performing various performance evaluation test on CEMS/ AMS located in Vadodara, Gujarat. Our scope of testing includes QAL-1 (Quality Assurance Level-1) , QAL-2, QAL-3, Annual Surveillance test, EN 14181, EN 15259, EN 15267-3 standards.

For more information,

www.tcqalabs.com