Covid-19 is a driving force for digitization

In an interview, Olaf Streit, Executive Sales Director Asia-Pacific @ AUCOTEC and Dileep Miskin, Director, ULESSPL(Aucotec-India) share how digital technology adoption can help the manufacturing sector in combating challenges posed by Covid-19 crisis and the future trends to watch out for. Excerpts:

Q1. Please share your views on how Covid-19 disruption is expected to accelerate the adoption of automation and digitization in manufacturing?

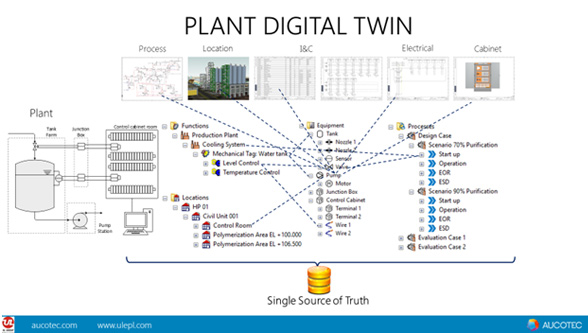

Digitization has recently become significantly more important: “This dire Covid-19 pandemic is also a driving force for digitization as the ability to work consistently in a globally distributed manner on a joint project and a web-based overview of project progress for everyone responsible are more important than ever. These are basic principles of Aucotec’s platform Engineering Base (EB), which are particularly relevant in times of compulsory working from home allowing to have the Collaborative , Multitasking & Multidiscipline working on the Engineering solution. Using EB the user can create the Digital Twin of the plant Model as shown in fig.1

Q2. In your opinion, what will be the role of these technologies in transforming and defining manufacturing in the post-Covid era.?

Aucotec has currently increased its support team for the provision of advice and support to its customers. The team helps swiftly and unbureaucratically, for example, in switching access from home workstations to the company’s own license server. All in all, however, the number of requests has not increased significantly. This shows how flexible and up-to-date EB is and that the system is keeping its promise to be an enabler for digitization at the highest possible level. Assuming that some of the current work scenarios and team collaboration technologies will be much more important even in the post COVID era compared to the past.

Q3. Which areas/segments within manufacturing will see the maximum adoption?

Better organization, structuring processes and tracking of progress to be always up-to-date will be more important than ever to make the right decisions based on information which are in-time. Paper and other conventional formats, even proprietary CAD formats will overcome as the density of information doesn’t match what is requested for reliable decisions. It will just speed up things which are already “on-the-way”. The modern era will see the entire plant documentation as built on mobile platform & enabled to write markups on the documentation which allows the field teams not to worry to have up-to-date documentation.