Precision engineering and manufacturing technologies company Renishaw is showcasing its diverse technology portfolio and extensive experience in automated process control at IMTS 2018, 10-15 September, in Chicago, USA.

At IMTS 2018, Renishaw is demonstrating its range of smart factory process control solutions, which are proven to help machine shops across many industries transform their production capabilities. Renishaw’s product portfolio supports the full spectrum of industrial metrology applications, delivering benefits in speed, ease-of-use and flexibility, which help manufacturers integrate smart factory technologies into their existing operations, today.

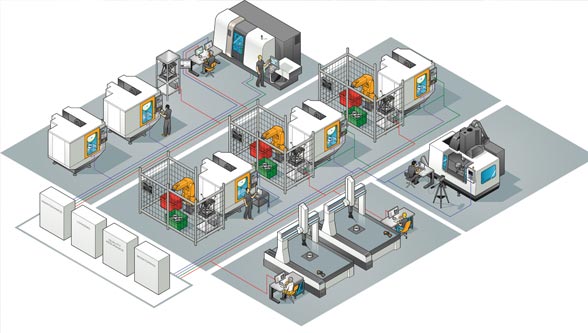

On display at Renishaw’s main stand in the Quality Assurance pavilion (Stand 135509, East Building, Level 3) is a high-productivity machining cell, featuring fully integrated process control. This demonstrates how high levels of automation and connectivity can be incorporated into CNC machining operations to improve productivity and process capability. The demo cell reflects process control techniques that Renishaw applies in its own factories to deliver highly automated precision manufacturing.

Manufacturers are increasingly recognising that flexibility to re-purpose equipment to accommodate shorter product life cycles and increased design variants is a significant benefit. Renishaw will showcase its latest technologies applied to the automotive and aerospace manufacturing industries. For example, the multi-sensor capability of the REVO™ system on co-ordinate measuring machines (CMMs). Rapid data acquisition of dimensional and surface finish characteristics on a single platform allows manufacturers to significantly reduce measuring time and provides actionable data more quickly.

On CNC machines, SupaScan uses the latest OSP60 probe to offer the world’s fastest workpiece set-up cycles. The system can also monitor surface condition (waviness), which is a critical-to-quality requirement for product efficiency.

The flexibility and range of applications of the Renishaw Equator™ gauging system is now increased. The new Equator 500 accommodates larger parts, and the introduction of IPC (intelligent process control) software allows manufacturers to automate process control and tool offset correction directly to CNC machines from any Equator gauge.

![]()