In the rapidly evolving landscape of manufacturing technology, the demand for higher precision and efficiency in machining processes is more pronounced than ever. Industry trends are increasingly leaning towards innovative solutions that offer superior performance while addressing environmental concerns. Among these advancements, HIWIN’s Underwater Direct Drive Rotary Table stands out as a game-changer, setting new standards in precision, durability, and eco-friendliness.

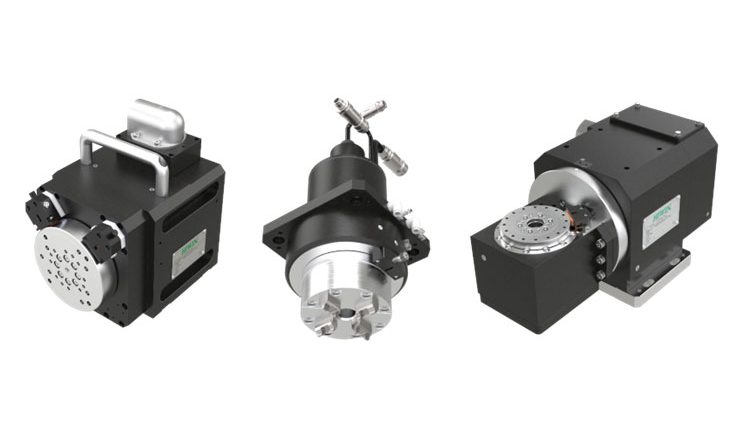

HIWIN’s Underwater Direct Drive Rotary Table is engineered to meet the rigorous demands of modern machining applications, including Wire Cut EDM, cleaning machines, and underwater ultrasonic testing machines. This rotary table combines long-term continuous operation with an IP68 waterproof rating, making it suitable for full immersion in water or oil. It accelerates to 1500 RPM within 0.3 seconds, enabling rapid and stable grinding of hard, brittle materials.

HIWIN’s Underwater Direct Drive Rotary Table’s superior performance is underscored by its ability to achieve a surface roughness of Ra0.2 micrometers, which is essential for high-precision applications such as those in the automotive, semiconductor, and medical industries. The machining efficiency is notably enhanced, with a productivity increase of 7.5 to 12 times compared to traditional methods. The positioning accuracy of ±3 arc-seconds is the highest in the industry, ensuring unparalleled precision and reliability.

HIWIN’s rotary table integrates intelligent leakage diagnosis and a normal closed braking system. These features not only improve the stability and safety of discharge machining processes but also boost the efficiency of machining operations by over tenfold compared to conventional mechanical rotary tables. This leap in performance is particularly significant in electrical discharge grinding, where the surface roughness of materials like tungsten, titanium, and cobalt can reach the Ra0.2 micrometer level. This advancement translates to a tenfold increase in production efficiency, elevating the overall capabilities of machining equipment and driving industry upgrades.

The technology behind HIWIN’s rotary table is based on a direct drive motor system, which offers several advantages over traditional drive mechanisms. By minimizing copper loss and achieving high energy conversion efficiency, this technology reduces carbon emissions by more than 55%. Additionally, it addresses the negative effects of magnetism during motor rotation, cutting down magnetic pole consumption by 50% and thereby lowering material costs.

Environmental sustainability is a core principle of HIWIN’s approach. The RCV-125E rotary table is designed with a focus on recyclability, with 90% of its materials being recyclable. This includes the motor coils, body components, and packaging materials such as wooden crates, which are all reused or recycled. This commitment to sustainability extends to achieving an IP68 rating for waterproofing and dustproofing, ensuring that the rotary table performs reliably even under the most demanding conditions.

HIWIN’s Underwater Direct Drive Rotary Table represents a significant advancement in machining technology. It combines high precision, efficiency, and environmental responsibility, setting a new benchmark for high-end machining applications. With its innovative features and sustainable design, this rotary table not only enhances manufacturing capabilities but also aligns with the growing trend towards eco-friendly and efficient industrial solutions.