Armes Maini: Empowering Industry With Integrated, Optimized Storage Solutions

Bangalore-based Armes Maini Storage Systems is renowned for its innovative and integrated storage solutions designed for warehouse automation, materials handling and archiving. Established in 2007 as a JV between Ferreto Group, Italy and Maini Group in India, the company brings together expertise and knowledge to offer bespoke solutions to its customers with a pan-India presence. A trendsetter in its domain, Armes Maini’s mission is to help its 1000 plus customers from all types of sectors to optimize use of space, improve their operational efficiency and enhance productivity and profitability using contemporary technologies and automation solutions, reveals S.A. Mohan, CEO & Director, in an interview with Engineering Review. Excerpts:

Q. How would you introduce your company to a new audience?

We at Armes Maini work together with our customers to provide optimized solutions for warehousing and storage requirements by designing, manufacturing and installing quality intralogistics systems. We are pioneers in the field of racking and storage solutions with a strong commitment towards innovation and technology and a wide spectrum of products catering to different applications, extensively engineered by our Italian partners, tailored to the individual requirement by the local technical team, produced from the state-of-the-art manufacturing facility, installed by experienced and trained professionals.

Q. What does your repertoire look like today?

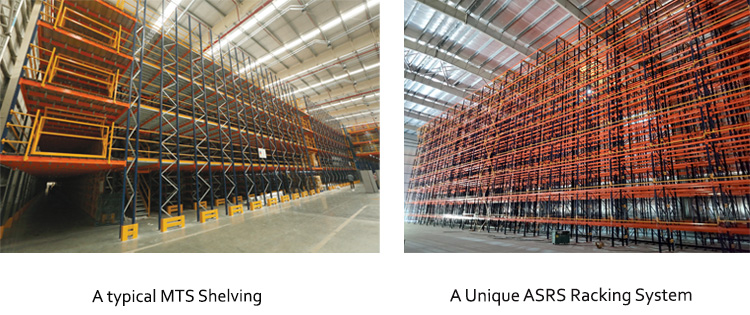

We are into every facet of storage and retrieval solutions viz bulk storage, part storage, mezzanine structures, semi-automated and automated solutions.

Q. Could you explain your multi-sectoral experience when it comes to providing storage solutions?

We deal with all types of sectors like FMCG, retail, 3PL, manufacturing, pharma and record management. The requirements and solutions vary from sector to sector. The solutions depend on the operations and throughput required for the specific sector/organization.

Q. Please update us on your capabilities in designing and installing ASRS. What are your offerings for warehouse automation?

Automatic storage and retrieval systems is an emerging segment. We have design and installation capabilities for structures as high as 30-40 meters. We have developed systems that support Stacker cranes, Radio shuttles, Mother and child shuttles, carton picking shuttles, Miniload stacker cranes, etc. We use three dimensional models for the design which facilitates in smooth integration with the automation systems.

Q. Could you explain seismic zone-3 compliant designs?

Seismic zone compliant structures can withstand a seismic event with minimum or no damages to the structure and the materials stored. It also ensures minimum damages to the external environment and the people around. With our Italian inspired designs we can offer superior structures in compliance with Indian and international standards. We derive the seismic spectrum specific to the locations considering various parameters and do a Modal analysis to arrive at time period of the structure. Non-linear static, Response spectrum analysis is conducted to simulate and design for the seismic forces. We use SAP-2000 as tool for our structural analysis.

Q. What makes your systems exceptionally sturdy and enduring? May we have a ringside view of your manufacturing excellence?

We use specially designed profiles made out of cold-forming technology for all our components. These profiles are carefully developed to have higher strength to weight ratio. We use high tensile steel procured from top steel manufacturers to form these components. We have state-of-the-art roll-forming machines to make different profiles like uprights, beams, bracings, walkways, decking, etc. Our fully automated powder coating line with SCADA controlled processes can handle 12m single piece components.

Q. What are the quality standards you have to conform to?

We are an ISO-9001-2005, ISO 14001-2015 & ISO 450001-2018 company with strong quality assurance process in place. We ensure traceability from raw material to final component by our unique process adopting latest technologies. One can get all the relevant details of the finished product by scanning the QR code attached to it.

Q. Can you single out a multi-tier shelving system you have executed recently? Why is it unique from the point of view of engineering?

We have recently executed a multitier shelving system for a retail giant. It was a seismic zone 4 compliant design with 4 tiers excluding ground tier with a capacity to store about 98,000 bins. The top tier was converted to a mezzanine floor with 600 Kg/sqm load capacity. This has to be executed in two phases for which presently two tiers have been installed. The system is designed in such a way that it can be expanded vertically w.r.t to the business needs at a later point of time. This complies with the latest relevant European and Indian standards.

Q. How do you go about executing turnkey projects, and what are the challenges involved?

We adopt the best Project, Manufacturing & Quality Management practices with unwavering focus on providing best value addition to our customers. Our milestones are derived based on customer business requirements and strategies and we align the entire organization towards achieving these milestones. Our execution plan will get derived by doing a project kickoff meeting coupled with preparing for the possible risks and mitigation plans within the cross-functional team.

We firmly believe in continual improvement of every process and incorporate the learnings from the previous experience. We carry out the training and development of human resources to instill the required technical and management skills. We proactively plan, identifying potential failures and contingencies which we could easily predict by our profound experience in handling larger projects with shorter timelines. We have a separate mechanism to attend to project specific contingencies within a short duration of time which is very important in achieving the milestones. The whole process is driven by our SAP-S4 Hana with customized modules. We ensure to apprise the status of the project to the Customer on a daily basis by sending the daily progress reports with the real time data. We usually anticipate, plan and prepare for certain project site related issues such as space constraint due to working warehouse, delays in site readiness due to general factors of green field project, etc.

Q. What are your major strengths?

We believe in our strong design capability for efficient customer oriented solutions, thoughtfully developed structural components, world-class manufacturing facilities backed up by our strong project management capabilities.

Q. What are the ground-breaking technological innovations you have introduced in the storage landscape? Also tell us about the design and engineering support you get from your parent company.

We were the first in the country to introduce the patented SIGMA profiles for our mezzanines which were very efficient compared to existing profiles. Some of our innovative products are our ZD shelves which require no bolts to assemble, profiled Decking surfaces which is 60-70% more efficient than conventional shelves, roll formed profiled walkway panels which can carry loads up to 1000 Kg UDL. We were the first company to comply with European standards as our designs originated from Italy and came to us through technology transfer. The parent company is always there for us for any kind of design and engineering support. We have a unique process for knowledge management so that we rarely have to use parent support for our day-to-day activities. For our strategic business/product development we use their experience and support.

India is one of the fastest growing economies in the world. Indian storage racking market was valued at USD 542.8 Mn in 2022 and is expected to grow at a CAGR of 10.3% to reach USD 1.4 Bn by 2032.The growth is majorly driven by Ecommerce sector supported by the growing economy.

Q. What’s your roadmap for Armes Maini to take it to the next level?

Armes-Maini is aiming to become a 500 Cr company in the next five years majorly driven by automation solutions and supported by conventional storage solutions.