India’s railway industry stands as a backbone to the nation’s infrastructure, connecting distant regions and facilitating the movement of goods and people. As the Indian Railways undergoes a transformative phase of modernization and electrification, the role of precision components in ensuring the efficiency and reliability of railway systems becomes paramount.

Importance of Railways Industry in India

The Indian Railways, known as the lifeline of the nation, plays a pivotal role in economic development, transportation, and connectivity. With an extensive network spanning the country, it is crucial to enhance the railway infrastructure for faster, safer, and more sustainable transportation.

Significance of Precision Components in the Railway Industry

Precision machining in the railway industry is imperative for achieving high-quality, reliable, and efficient railway systems. Precision components contribute to the overall performance, longevity, and safety of railway operations. As the industry progresses towards electrification, the demand for precision parts becomes even more critical for the seamless functioning of electric and diesel locomotives.

Railway Components Machined by Mazak High Precision Machines

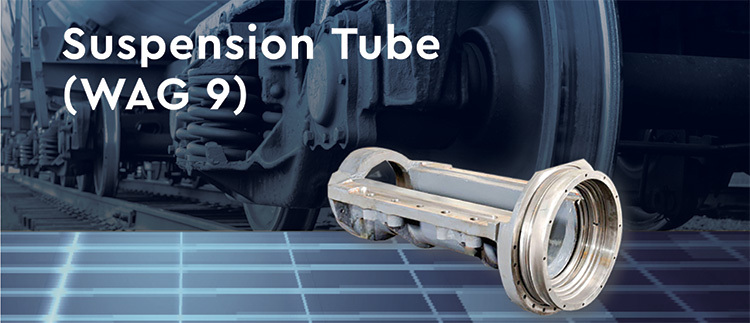

Mazak, a leader in precision machining technology, plays a vital role in shaping the future of the Indian Railways. The company specializes in machining major precision parts of the Drive System of a Railway Locomotive. Notable components include the Suspension Tube, Traction Motor Housing, and Axle Box.

Traction Motor Housing and Suspension Tube

Among the essential components, the Traction Motor Housing and Suspension Tube are integral to the functioning of traction motors in locomotives. These components demand a high level of precision, and Mazak’s High Precision Horizontal Machining Center HCN8800 is the preferred choice for machining them.

- Precision Alignment: Mazak’s CNC machines excel in achieving high levels of concentricity, ensuring perfect alignment of both end bores in the traction motor components. This precision is vital for optimal traction motor performance, minimizing wear and ensuring longevity.

- Increased Productivity: The faster machining processes of Mazak machines contribute to increased overall productivity in the manufacturing of traction motor components.

- Complex Machining Operations: Mazak CNC machines allow for complex machining operations to be performed in a single setup, reducing the number of setups required and contributing to time and labor savings.

- Reliability and Repeatability: The reliability and repeatability of Mazak CNC machines ensure consistent and accurate production of components, reducing the risk of defects and ensuring product longevity.

- High-Quality Output: The precision and accuracy of Mazak CNC machines contribute to the production of high-quality traction motor components, meeting stringent industry standards.

The precision and accuracy of Mazak CNC machines contribute to the production of high-quality traction motor components, meeting stringent industry standards.

Mazak Machines – Achieving Success:

Mazak’s commitment to precision and innovation extends beyond the machinery itself. The company offers turnkey solutions with advanced tooling and technology. With a dedicated project management team, in-house fixture and tool designing capabilities, and a state-of-the-art Technology Center in Pune, Mazak demonstrates its commitment to excellence.

Mazak’s high-precision machines are instrumental in propelling the modernization and electrification initiatives of the Indian Railways. By machining crucial components with unmatched precision, Mazak contributes significantly to the overall quality, reliability, and efficiency of railway systems, playing a vital role in shaping the future of rail transportation in India.