The atmospheric air contains moisture, particle contaminants, microorganisms, and gases. When this air gets compressed, the concentration of such particles increases by 6 to 10 times. However, when this atmospheric air gets compressed by an air compressor, other contaminants like oil and metal traces get added during the compression process. That is why removing these contaminants is essential before using compressed air across any application.

These contaminants are categorised as:

- Particles

- Water (Liquid, vapor, and aerosol)

- Oil (Liquid, vapor, and aerosol)

- Microorganisms

- Other gases

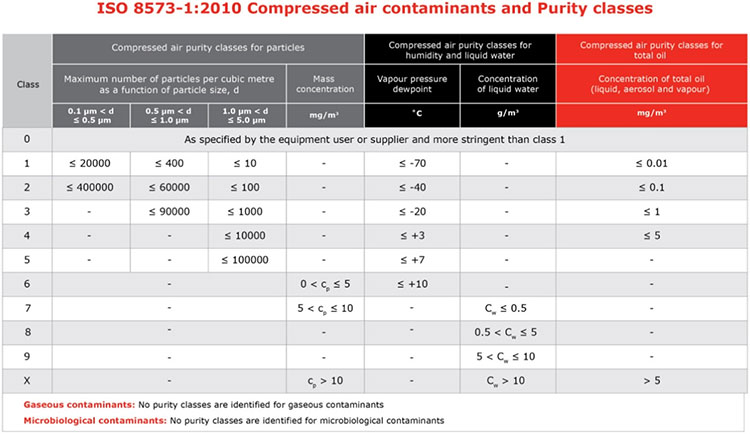

According to the International Standard, ISO 8573-1:2010, the segregation of compressed air contaminants like particles, water, and oil are as per purity classes. Microorganisms and other gases are not get included in this standard. As a result, the air purity is indicated as [P, W, O] and ordered as per the amount of particles, water, and oil.

Based on the application requirement, contaminants are removed from the compressed air by using suitable downstream equipment. For instance, particle, water, and oil contaminants can be removed from the compressed air using downstream filters.

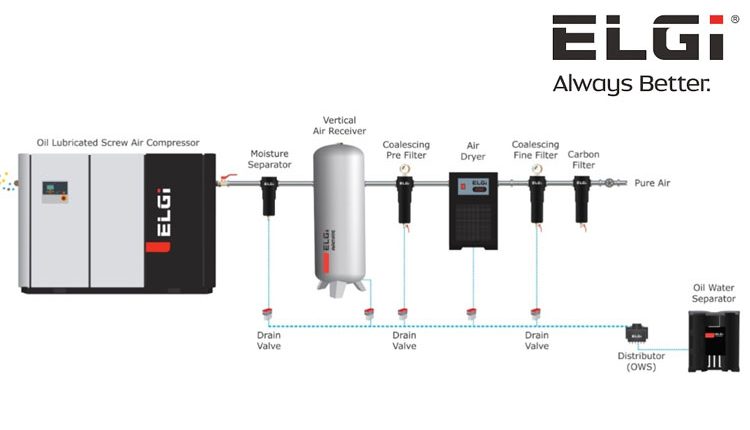

Bulk moisture separators are recommended for removing the water from the compressed air.

- It is mandatory to have a proper automatic drain and the moisture separator that are used after the cooler. The optimal removal of condensate will ensure that no bulk water carry over to the downstream equipment. It is recommended to use Level sensing zero loss drain and moisture separator to get this done with minimum loss of air.

- Downstream filters are available in various configurations/types. These can be categorized as per the residual oil and particle after filtration and are as follows:

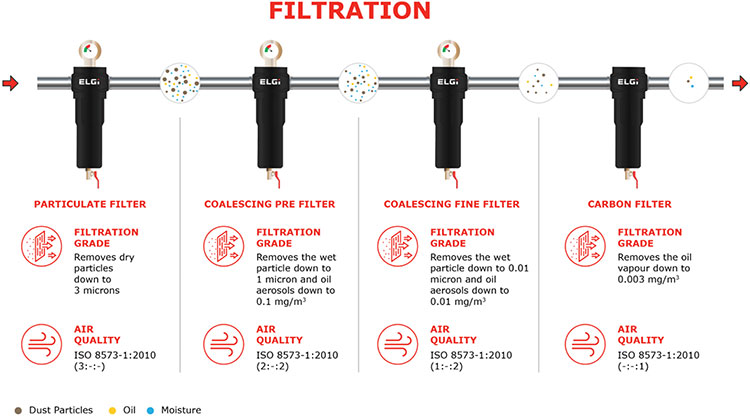

1. Coalescing filters are recommended to remove the wet particles and aerosols (water and oil) from the compressed air. Different types of coalescing filters are available based on residual oil and particle content at the filter outlet after filtration. Coalescing filters are classified into two types:

o With the Pre-filter, we can achieve class 3 or class 2 purity of particles and oil, i.e., ISO 8573-1:2010 [2: -:2]

- The recommended sequence of installation is the bulk moisture separator followed by pre-filter

o With the fine-filter, we can achieve class 2 or class 1 purity of particles and oil, i.e., ISO 8573-1:2010 [1: -:2]

- The recommended sequence of installation is bulk moisture separator, pre-filter, dryer followed by a fine filter

2. The particulate filter is specialised to remove the dry particle and microorganisms from compressed air. This filter is mainly used after a desiccant dryer to ensure that the desiccant particles are not carried to the compressed air line.

- The class of purity of particles made possible with this filter is 3,4,5 and 6, i.e., ISO 8573-1:2010 [3: -: – ]

- The recommended sequence of installation is the bulk moisture separator, pre-filter, Desiccant dryer followed by the particulate filter

3. Carbon filters are recommended to remove the oil vapour and other gases present in the compressed air, which are not removed by coalescing filters.

- The class of purity achievable with carbon filter is ‘’1’’, i.e., ISO 8573-1:2010 [-: -:1]

- The recommended preceding with carbon filter would be pre-filter, dryer, fine filter, followed by carbon filter.

Important factors to consider for the right selection of filters and ensuring their optimal performance

- The filter capacity is based on the operating pressure of 7 bar (nominal condition). If the operating pressure is different, it is essential to use the correction factor and select the filter model accordingly.

- The correct sequence of installing filters must be followed for optimal performance. As a thumb rule, the level of filtration should be in sequence, ranging from 20 ppm to 5 microns or from 10 microns to 1 micron to 0.01 micron. Carbon filters should always follow after the 0.01 micron filter. In the absence of this sequence, it will choke up faster and reduce the lifespan.

- Please note that the lowest pressure drop across filters happens when the filter elements are dry. If the filter element gets wet, delta P will increase. This is another reason why we should follow the above-mentioned sequence.

- Since the pre-filter is mostly used before the dryer, it is recommended to have a proper drain and the pre-filter. The regular removal of condensate will ensure that no moisture carries over to the downstream equipment.

- The replacement of the filter element at the recommended service interval is essential. The filters have an indicator of saturation level, and it is recommended to replace the filter element in case of indication. Saturated filter elements will not give the required class of purity. This will have a higher pressure drop, creating an extra load on the compressor. As a thumb rule, 0.14bar/2 psi pressure drop will have 1% additional load on the compressor. Carbon filters function on the adsorption method and need to be replaced on a timely basis.

- The oil emulsified condensate is collected from various downstream equipment and the compressor. After this, the condensate needs to proceed for oil removal before discharging to the sewage.

- If the oil emulsified condensate is discharged to the ground, the water will eventually evaporate, leaving the oil behind.

How to select an oil-water separator to remove the oil from the oil emulsified condensate before discharging into the sewage

- Selecting the correct oil-water separator element is vital for removing oil from the condensate within the permissible limits allowed in the region. This is expressed in terms of ppm units. Usually, it is set from 10 to 15 ppm.

- It is important to see that the oil-water separator selected is compatible to operate with the compressed air and condensate mixture flowing through the condensate line.

- The PPM level after separation needs to be monitored thoroughly. If the PPM level is above the recommended level, then the element needs to be replaced. Some of the oil-water separators also have a life indicator for elements to ensure ease in identification

Here are the best practices for removing contaminants from your compressed air system:

- Select the correct size of moisture separators so that maximum bulk moisture is removed from the system and not carried over to the downstream equipment

- Select the correct coalescing filter type, rating, size, and appropriate preceding level for the selected filters. Here, it is essential to replace the filter element at proper service intervals.

- Electronic drains play an important role in removing the condensate from the compressor and downstream equipment. Here, it is essential to properly maintain and replace an electronic drain regularly, as per recommendations.

- Dryers must be before the fine filter and carbon filter to ensure the compressed air is free from water vapour. This is critical, as the vapour can choke the filter element. A particulate filter is recommended after the desiccant dryer before fine and carbon filter

- If a small part of the application requires more stringent air quality, it is recommended to have an additional dryer and filter set near the point of use. Usually, this dryer could be a membrane or desiccant type giving a lower dew point.

- Monitor and check for leakage in the compressed air pipelines. A leakage can give a chance for the outside contaminants to get into the compressed airline. These leakages allow outside air to creep inside the piping when the compressor is stopped (when there is no positive pressure inside the pipe). This leak allows moisture to rust and carries other impurities inside the pipe, which, in turn, may get carried forward when the compressor restarts.

Conclusion

Once you have attained the purity class suitable for your application, it is essential to maintain the same and not add any further impurity. Sometimes, this can happen with the usage of mild steel pipes and fitments, shedding out the rust in the line, which can reach your application. Therefore, it is recommended to use suitable piping like aluminium, or a suitable rust preventive coating like galvanized iron. Moreover, it is also suggested to check and replace these pipes based on their life and corrosion level.

About The Author,

Rajshekhar Mahendrakar,

DGM, Product Management,

ELGi Equipments Ltd.