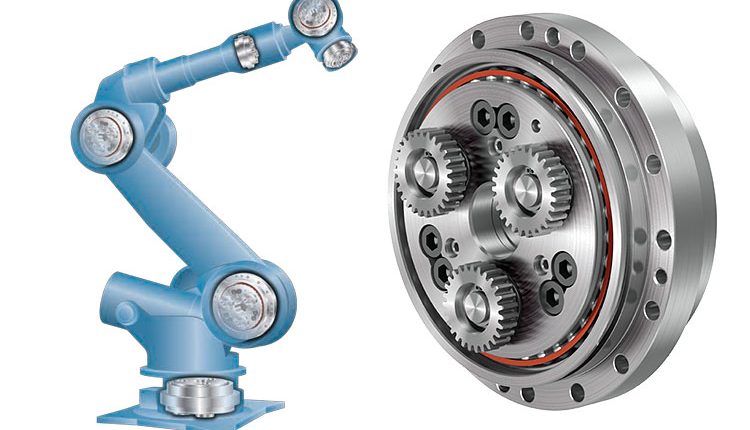

Nabtesco is the world’s leading manufacturer of Precision reduction gears and are mainly used in the Industrial High-speed robots and Machine tools application accessories to achieve accurate positioning movement and high rigidity. Nabtesco Precision reduction gears have long been used in the joints of industrial robots to support their accurate and powerful motion. Nabtesco’s stellar track record in this field covers more than 30 years.

Nabtesco is the world’s leading manufacturer of Precision reduction gears and are mainly used in the Industrial High-speed robots and Machine tools application accessories to achieve accurate positioning movement and high rigidity. Nabtesco Precision reduction gears have long been used in the joints of industrial robots to support their accurate and powerful motion. Nabtesco’s stellar track record in this field covers more than 30 years.

Nowadays, Nabtesco’s precision reduction gear is used in many fields in addition to industrial robots and machine tools, including FPD production machines, semi-conductor production machines, etc., due to its high accuracy, high rigidity and compactness.

What is Precision Reduction Gear RV™?

Precision reduction gear RV™ is a reduction gear for precise motion control which uses a planocentric reduction gear mechanism. This reduction gear design has advantages in rigidity and resistance against overload with a compact body due to a large number of simultaneously engaged gear teeth. Furthermore, minimal backlash, rotational vibration and low inertia lead to rapid acceleration, smooth motion and accurate positioning.

Precision reduction gear RV™ is a reduction gear for precise motion control which uses a planocentric reduction gear mechanism. This reduction gear design has advantages in rigidity and resistance against overload with a compact body due to a large number of simultaneously engaged gear teeth. Furthermore, minimal backlash, rotational vibration and low inertia lead to rapid acceleration, smooth motion and accurate positioning.

Cycloidal gears offer unbeatable advantages

The two-stage reduction of cycloidal gears makes solutions from Nabtesco so successful. The reason is that the speed is reduced by the double cams. In addition, vibration is reduced by the two-stage reduction principle and low inertia. The force is also distributed very evenly due to the roller cam design, and this contributes to the minimum hysteresis loss and enormous resistance to shock loading.

The drive or servomotor is connected to the spur gear stage of the gearbox via a pinion. The rotating speed reduces at this point relative to the reduction ratio between the pinion and planetary gear. The planetary gears are connected to crankshafts which drive the cams using needle bearings. These cams rotate inside the case which is lined with pins.

Precise

The cycloidal design of the precision reducer ensures extremely precise operation throughout the entire life cycle, with a hysteresis loss of less than one arc. minute. The gear systems are designed for high repeatability, positioning and rotational accuracy to allow exact positioning even at high speeds and accelerations.

Robust

Nabtesco gears are extremely robust, durable and low-wear. They feature high overload capability and extreme rigidity, and are insensitive to vibrations. The integrated angular ball bearings absorb axial and radial loads, as well as bending moments, which makes the gears highly resistant to impacts and overloads.

Compact

The high torque density of the low-backlash precision gears enables an extremely compact design. The precision reducers are lightweight, space-saving, and efficient – ideal for all applications requiring high performance and a compact design.

High shock resistance in emergency stop situations

The cam has exactly one eccentric section less than the pin ring has pins. A 360° revolution of the crankshafts therefore causes the cams to rotate one pin farther, whereby practically all the gear teeth are in continuous contact with the pins. The rotating movement is then transmitted from the input shaft to the crankshafts via the spur gear stage, and these then shift the cams in the pin ring and, consequently, generate a reduced speed with high precision. This technology enables the RV gears to absorb 5 times the rated torque in emergency-stop situations without suffering any damage. The resulting overall reduction is the same as the product of the two reduction ratios (spur gear stage and eccentric stage).

“RV” stands for our gear’s “rotor vector” type of construction, and thus also for their extremely high resilience and precision.

Advantages

- High accuracy (backlash & lost motion : Less than 1 arc.min.)

- High rigidity

- High shock load resistance

- High torque density (High torque & Compact body)

- Wide range of reduction ratios

- Minimal vibration

State-of-the-art bearing concept

All cycloidal gears made by Nabtesco come with a strong, integrated main bearing that boasts large angular ball bearings and a multitude of rolling elements. This allows them to absorb bending moments that are 250% greater than the ones that can be absorbed by conventional planetary gears of comparable size. The robust bearing lets cycloidal gears also serve as a supporting element in a robot / machine or plant, eliminating the need for an additional external bearing. This makes it possible to manufacture more compact designs, reduce the engineering and installation expense and bring down cost.

Integrated main bearing:

- Absorption of great bending moments

- A supporting machine element

- No additional external bearing required

- Handling of heavy loads

- Manufacture of more compact robots, machines and plants

- Reduced costs of engineering & installation.

For more details: Website: www.nabtesco.co.in