To achieve high flexibility of the safety system of the plant, the light curtains, muting sensors safety switches and e-stops used are handled by the Mosaic Safety Controller.

The need is protecting a palletising system characterized by a platform palletiser able to stack boxes of different heights.

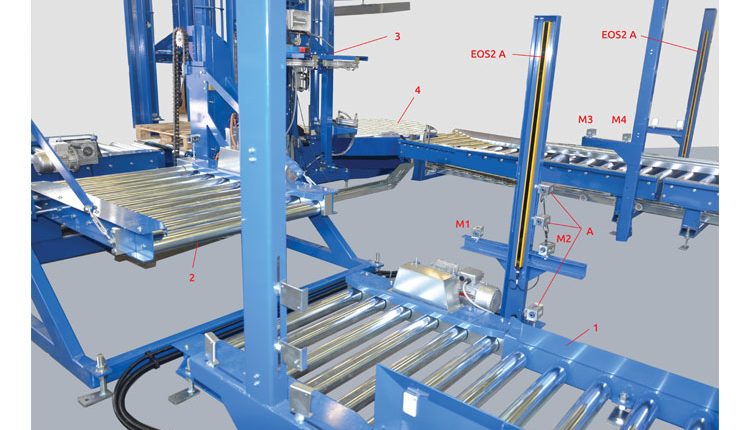

Palletising system

- The boxes, that might have different heights, are loaded on the roller conveyor 1.

- Photocells, indicated in the figure by the A letter; ensure the measurement of the height of the box (the palletizer is able to handle boxes with two different heights).

- In order to protect the box entrance, the dangerous area of the machine, before the lift 2, there is an EOS2 A safety light curtain with 90 mm resolution and bidirectional muting (input and output). Two photocells M1 and M2 are used as muting sensors.

- The box is raised, rotated (90°) than it enters the platform palletiser 3 which stacks the boxes on the pallet.

- The full pallet moves to the wrapping machine 4 that wraps it up with the film for packaging.

- Protecting the box output, there is an EOS2 A safety light curtain with 90 mm resolution and unidirectional muting func tion (output only). Two photocells M3 and M4 are used as muting sensors.

The protection system has been completed with:

- 2 EOS2 A light curtain (automatic start/restart)

- 4 photocells

- MOSAIC safety controller + Expansion module. This guarantees a high level of flexibility of the safety system.

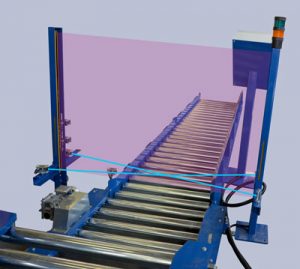

Two-way openings with pallet entrance/exit

The two photocells used as muting sensors are placed on both sides in relation to the vertical light curtain.

The muting function is activated following simultaneous interruption of the 2 sensors within a programmable sensor time. This time can be set through the Mosaic’s parameter: Sensor time (from 2 sec. to 5 sec.).

The Muting function remains active as long as both sensors re- main occupied. When the first of the two sensors is cleared, the Muting function is disabled.

The maximum duration of the Muting condition (timeout) can be set from 10 seconds to infinity, using the Mosaic’s parameter: Timeout.

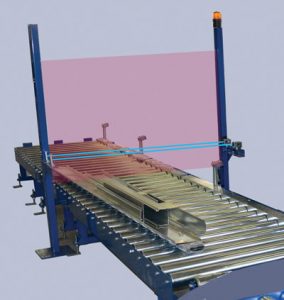

One-way openings with pallet exit

The two photocells, with muting sensors function, are on the same side of the vertical light curtain and are placed in front of the dangerous opening.

The Muting function is activated following simultaneous interruption of the 2 sensors within a programmable sensor time. This time can be set through the Mosaic’s parameter: Sensor time (from 2 sec. to 5 sec.).

Muting function remains active as long as both sensors remain occupied.

When the first of the 2 sensors is cleared, the material has a programmable time to abandon the guarded area delimited by the light curtain. This time can be set through the Mosaic’s parameter: End of Muting time (from 2,5 sec. to 6 sec.).

The Muting condition will be disabled as soon as the protected area is cleared. If the light curtain is still occupied, the OSSD out- puts are disabled, interrupting the functioning of the machine.

In order to prevent the plant stopping in case of protruding parts, or an oscillation of the pallet re-occupy the light curtain after the muting sequence is completed, Mosaic provides the Blind Time function (from 250 msec to 1 sec). This parameter defines how long, with muting sequence completed, the light curtain can be re-occupied without generating alarms. Maximum 1 sec.

The maximum duration of the Muting condition (timeout) can be set from 10 seconds to infinity, using the Mosaic’s parameter: Timeout.

For more information, Website: www.reersafety.it